Copper foil tape is a type of tape that has one or two thin layers of copper foil on one or each side. Common uses for this tape in electrical and electronic applications include grounding and shielding, as well as connecting various components. Professionals frequently use this material because it is easy to work with, long-lasting, and adaptable.

To You-San technology, copper Tape series mainly includes P1500Series Nano Carbon Copper Tape, P0700Series Single Conductive Copper Tape and P0700DSeries Double Conductive Copper Tape.

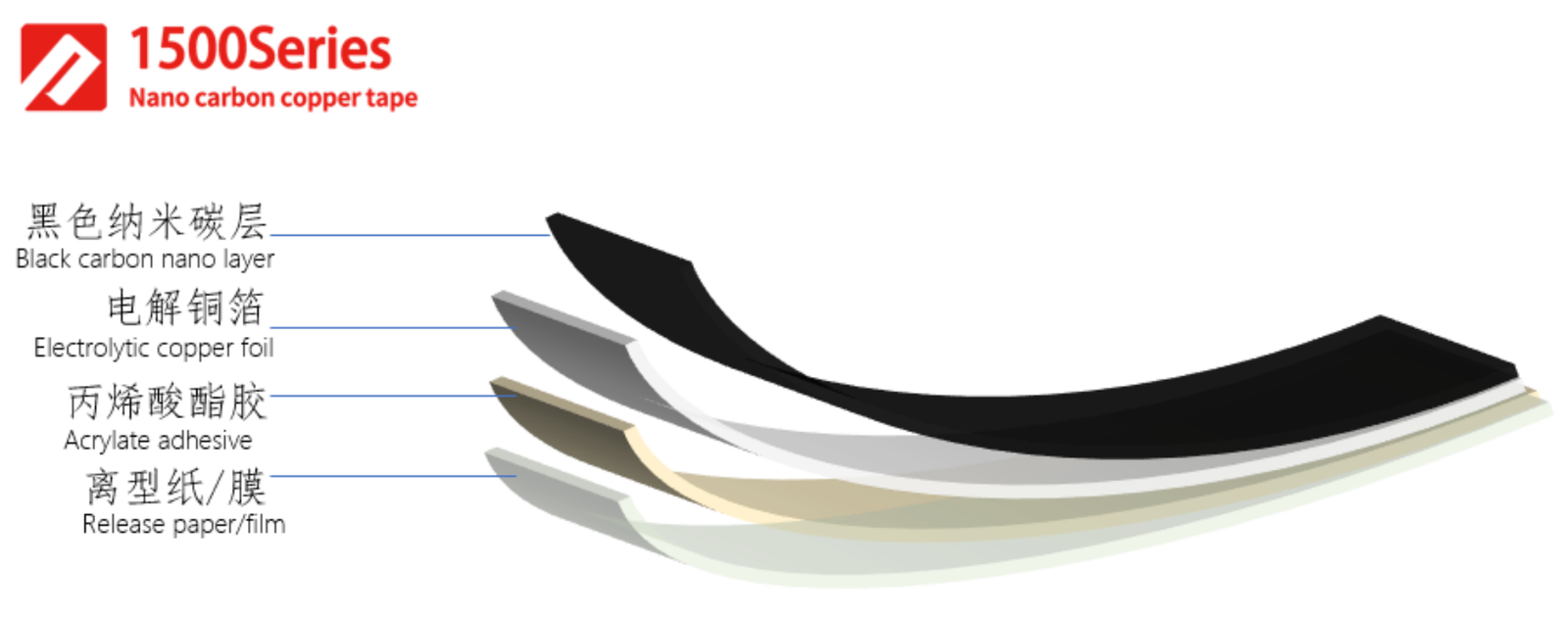

Product structure diagram of nano carbon copper foil tape

|

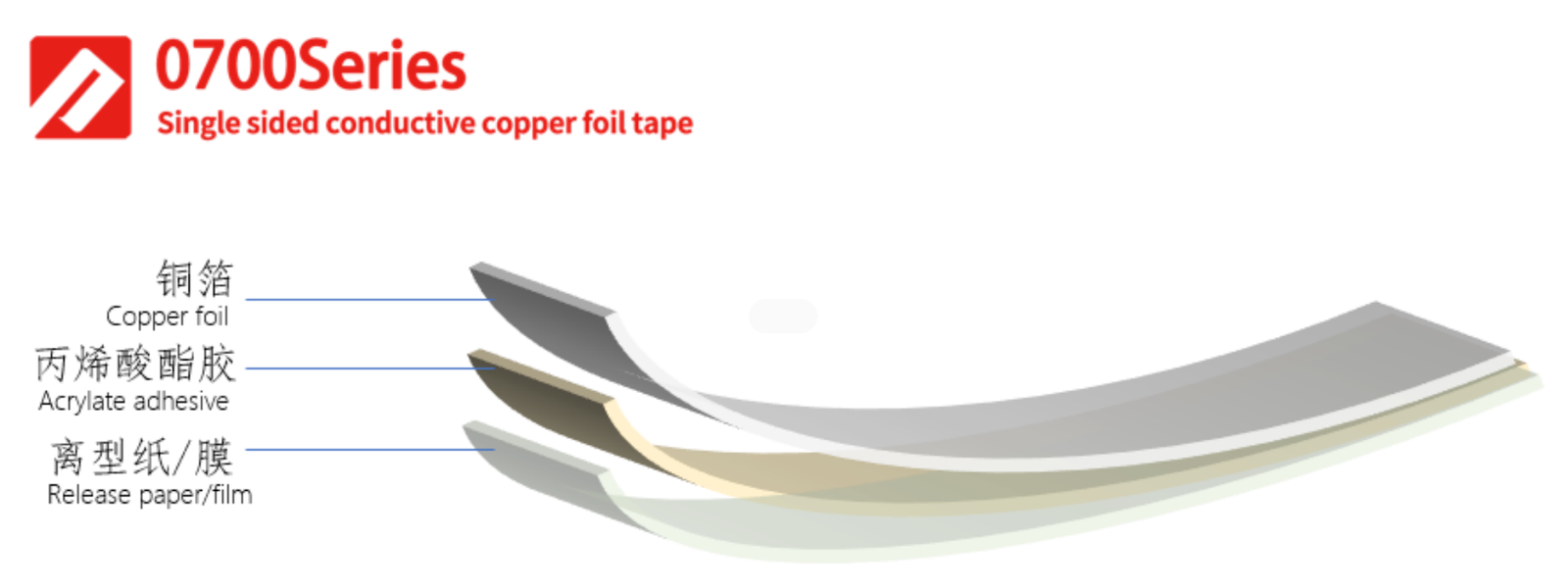

Single-conductor copper foil tape product structure diagram

|

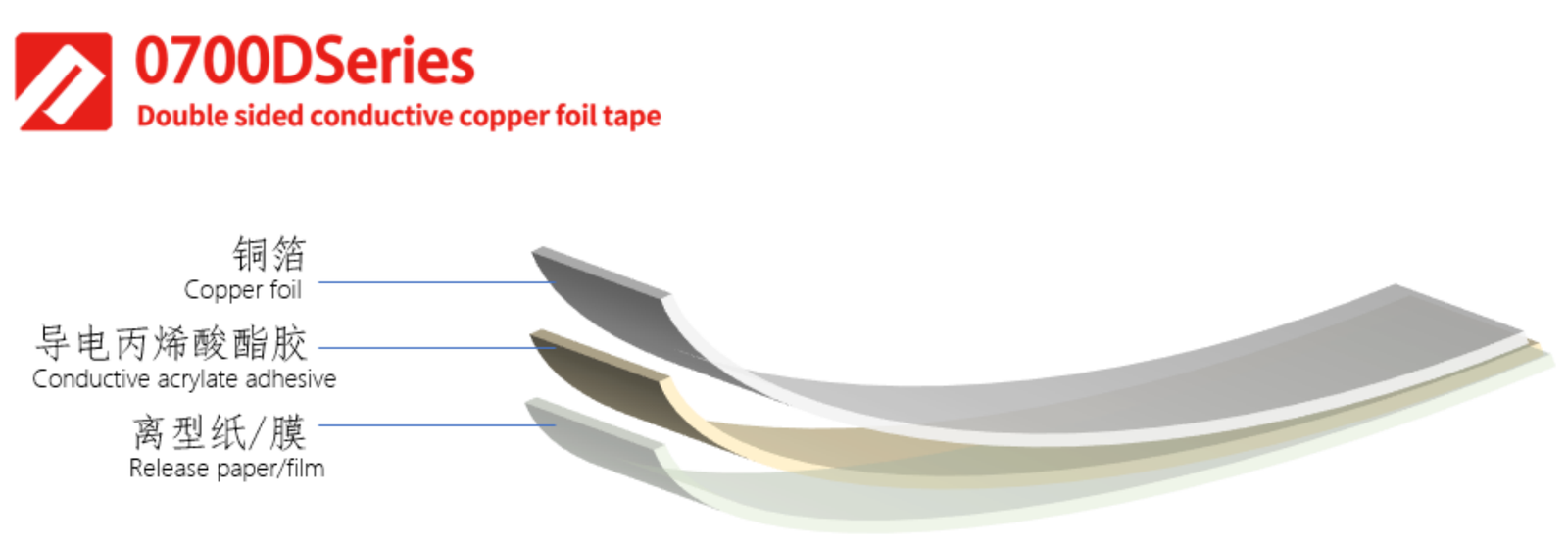

Product structure diagram of double-conducting copper foil tape |

Main application:

1.Connection conduction: connection conduction of internal structural parts of electronic devices such as mobile phones, tablets, computers, etc.

2.Signal shielding: Signal shielding for mobile phones, computers, navigators and other electronic devices with communication functions.

3.Anti-electromagnetic interference: mobile phones, televisions and other communication devices, as well as printers, scanners and other electronic devices to prevent signal interference.

4.Thermal Conductivity and Dissipation: Thermal conductivity and dissipation of all electronic and electrical equipment such as mobile phones, computers, televisions, etc.

5.Cable shielding: Electromagnetic shielding of wires, cables and plug-in materials.

Signal Shield |

Connection Conductivity |

|

|

|

Thermal conductivity and heat dissipation |

EMI (electromagnetic shielding) |

|

|

|

Electrically conductive shielding |

Memory Stick Thermal Conductivity |

Product Parameter Table of Nano Carbon Copper Foil Tape

Test items Test method Unit Product Type P1503 P1505 P1506 P1508 P1510 P15155 Color Visual inspection – black black black black black black Type of glue – – Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Base material – – Nano carbon copper foil Nano carbon copper foil Nano carbon copper foil Nano carbon copper foil Nano carbon copper foil Nano carbon copper foil Substrate thickness ASTM D-3652 mm 0.009 0.03 0.03 0.05 0.07 0.07 Total thickness ASTM D-3652 mm 0.03 0.05 0.06 0.08 0.09 0.155 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 10(4) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 15(6) Room temperature retention GB/T4851-1998 H 8 12 12 12 12 24 Base thermal conductivity ASTMD5470 W/mk 400 400 400 400 400 400 Thermal conductivity of composite layer ASTMD5470 W/mk 600~800 600~800 600~800 600~800 600~800 600~800 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120

Product Parameter Table of Single Conductor Copper Foil Tape

Test items Test method Unit Product Type P0703 P0705 P0706 P0707 P0709 P0712 Color Visual inspection – Copper natural color Copper natural color Copper natural color Copper natural color Copper natural color Copper natural color Type of glue – – Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Base material – – Copper foil Copper foil Copper foil Copper foil Copper foil Copper foil Substrate thickness ASTM D-3652 mm 0.009 0.018 0.025 0.035 0.05 0.075 Total thickness ASTM D-3652 mm 0.03 0.05 0.06 0.07 0.09 0.12 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 8(3.2) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 15(6) Room temperature retention GB/T4851-1998 H 12 12 12 12 12 24 Surface resistance (copper foil surface) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120

Product Parameter Table of Double Conductor Copper Foil Tape

Test items Test method Unit Product Type P0703D P0705D P0706D P0707D P0709D P0712D Color Visual inspection – Copper natural color Copper natural color Copper natural color Copper natural color Copper natural color Copper natural color Type of glue – – Conductive acrylate adhesive Conductive acrylate adhesive Conductive acrylate adhesive Conductive acrylate adhesive Conductive acrylate adhesive Conductive acrylate adhesive Base material – – Copper foil Copper foil Copper foil Copper foil Copper foil Copper foil Substrate thickness ASTM D-3652 mm 0.009 0.018 0.025 0.035 0.05 0.075 Total thickness ASTM D-3652 mm 0.03 0.05 0.06 0.07 0.09 0.12 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 8(3.2) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 15(6) Room temperature retention GB/T4851-1998 H 4 12 12 12 12 24 Surface resistance (horizontal, adhesive surface) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Surface resistance (vertical) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Base thermal conductivity ASTMD5470 W/mk 400 400 400 400 400 400 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120