|

|

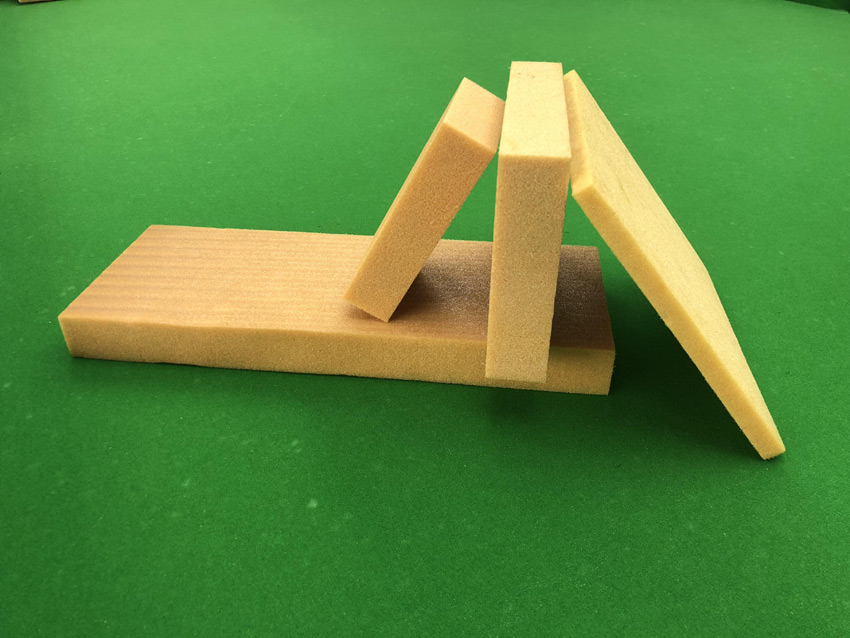

Polyimide (PI) refers to a class of aromatic heterocyclic high-molecular-weight compounds with imide functional groups incorporated into their molecular structure. Initially developed to meet the urgent demand for heat-resistant, high-strength, lightweight structural materials in the aerospace field, polyimide is currently considered the top-tier polymer material in terms of comprehensive properties. Polyimide foam combines the advantages of polyimide resin and porous materials, and possesses characteristics such as light-weight, radiation resistance, sound absorption and noise reduction, wide temperature range resistance, flame retardancy, thermal insulation, low smoke density, and environmental friendliness. It is the most advanced foam material in terms of comprehensive properties among polymer materials.

Polyimide exhibits excellent performance, including high temperature resistance, low temperature resistance, strong electrical insulation, thermal expansion coefficient similar to that of metals, outstanding mechanical and processing properties, non-toxicity, and inherent flame retardancy. These characteristics make it widely applied in various fields and play an irreplaceable role.

1.Heat resistance: Polyimide has a thermal decomposition temperature of 550°C, making it the most heat-stable polymer.

2.Low temperature resistance: It does not become brittle in liquid helium at -269°C.

3.Excellent mechanical properties: It is comparable to steel.

4.Outstanding wear resistance: It is suitable for high-strength and wear-resistant applications.

5.Good processability: It can be processed using various methods commonly used for polymers.

6.Good dielectric properties: It maintains insulation properties over a wide temperature and frequency range.

7.Non-toxic: It is inherently non-toxic, with zero volatile organic compounds (VOC).

8.Acid, alkali, salt, and oil resistance: It is insoluble in most acids, alkalis, and oils.

9.Flame retardancy: It is inherently flame retardant, with low smoke density, low toxicity, and low smoke emission.

1.Inherent flame retardancy: It is inherently flame retardant and can achieve the A-0 level of fire resistance.

2.Ultra-low thermal conductivity: Its thermal conductivity is ≤0.04 (W·m-1·K-1).

3.Non-absorbent, anti-condensation, and water-insensitive.

4.High and low temperature resistance: It can withstand temperatures ranging from -260°C to 350°C.

5.Zero VOC emissions and odorless.

6.Environmentally friendly and non-toxic.

7.Good toughness and resilience, not easily damaged.

8.Lightweight with a density as low as 6 kg/m³. Ø Acid, alkali, and oil resistance.

9.UV resistance. Ø Good weather resistance. Ø Non-flaking and resistant to mold. Ø Extremely low smoke emission, with a smoke density less than 15.

Compared to other high-performance insulation materials currently available on the market, polyimide foam stands out in terms of its various properties, making it an ideal choice in the field of new materials. Its flame retardancy, absence of volatile gases, non-toxicity, weather resistance, water repellency, acid and alkali resistance, and overall performance are far superior to other materials.

With its high mechanical strength, weather resistance, flame retardancy, and high and low temperature resistance, polyimide foam is suitable for structural components that require insulation, low density, and high stability.

1.It has a uniform closed-cell structure with pores of approximately 0.2-0.3mm.

2.It exhibits high temperature resistance and compression creep resistance, maintaining good dimensional stability in temperatures ranging from -260°C to 250°C.

3.It has low dielectric constant, high insulation properties, and low water absorption.

4.It finds wide applications in aerospace, aviation, shipbuilding, rail transportation, automotive manufacturing, unmanned aerial vehicles, radar, 5G communication, new energy, and sports and entertainment equipment.

Polyimide Foam Product Specification Table

Main properties Test standards Units Values Density GB/T 6343 kg/m3 20 Thermal conductivity GB/T 10295 W/(mK) ≤0.040 Compressive creep deformation GB/T6669 % ≤10 Moisture absorption rate GB/T 5480 % ≤0.05 Tensile strength GB/T 6344 KPa ≥60 Flame resistance GB/T 2408 V-0 Oxygen index GB/T2406 % ≥32 Low toxicity at room temperature GJB 3881 fulfil Smoke density and toxicity at high temperatures FTP Part 2 fulfil Low flame propagation FTP part 5 fulfil Radiation resistance JIF 1018 fulfil