You-San Technology’ aluminum foil tape series mainly includes four major categories: P1300Series Nano Carbon Aluminum Foil Tape Series, P0600Series Single-sided Aluminum Foil Tape Series, P0600D Series Double-sided Aluminum Foil Tape Series and P0900Series Mylar Aluminum Foil Tape Series.

Let’s see the product features of them.

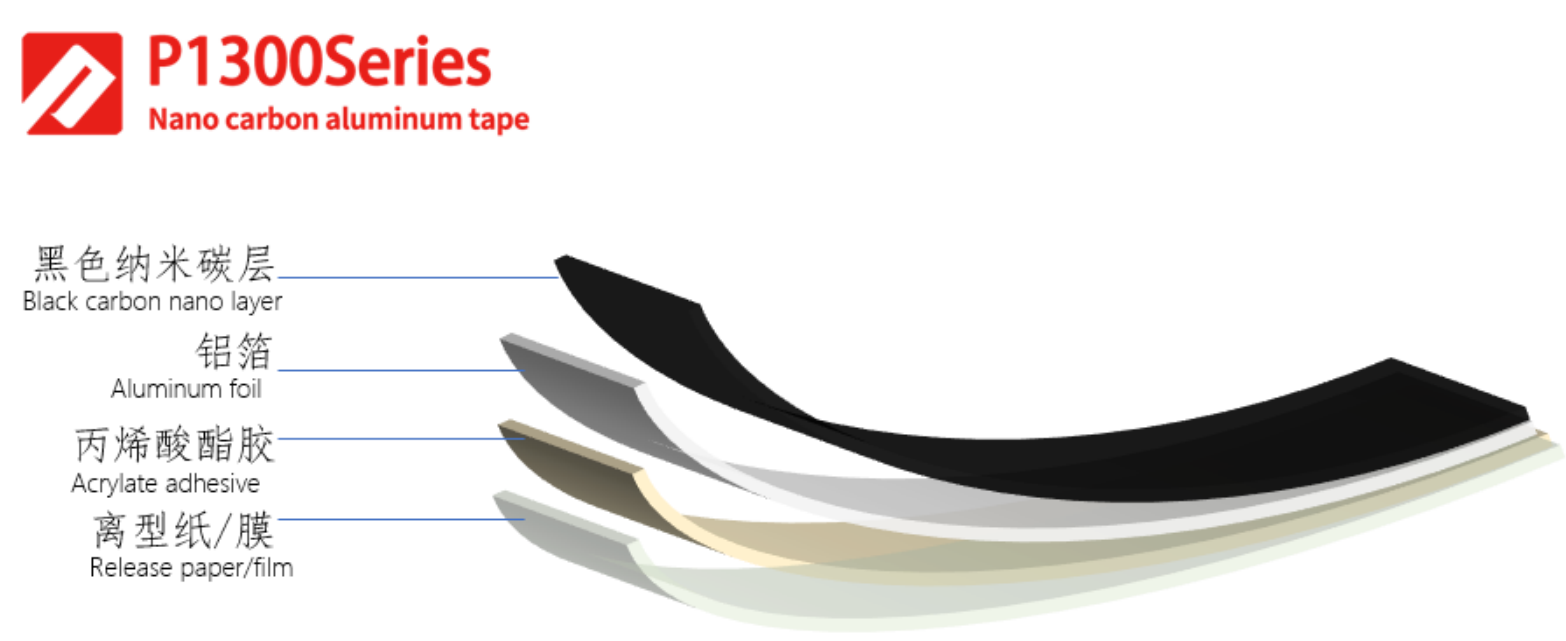

P1300Series Nano Carbon Aluminum Tape:

Excellent thermal conductivity and heat dissipation performance

Good flexibility, processability, and repairability.

EMI shielding and absorption to protect sensitive electronic components

Product Structural Diagram of Nano Carbon Aluminum Tape

P0600Series Single Conductive Aluminum Foil Tape

Aluminum surface conductive with excellent interference shielding effect.

Good electrical conductivity, thermal conductivity, and temperature resistance.

Strong peeling strength, which allows it to be bonded with various polar and non-polar materials.

Product Structural Diagram of Single Sided Aluminum Tape

P0600DSeries Double Conductive Aluminum Foil Tape

Aluminum surface conductive and adhesive conductive with excellent interference shielding effect.

Good electrical conductivity, thermal conductivity, and temperature resistance.

Excellent peeling strength, which allows it to be bonded with various polar and non-polar materials.

Product Structural Diagram of Double-sided Aluminum Tape

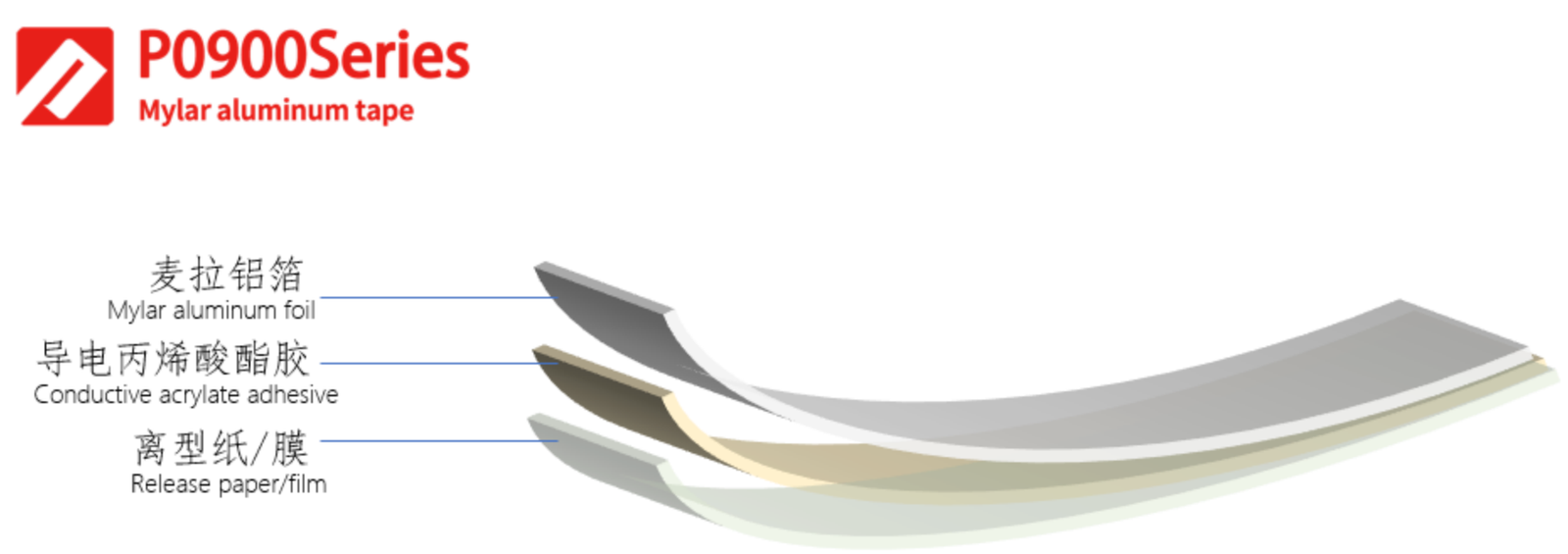

P0900Series Mylar Aluminum Foil Tape

High tensile strength and brightness.

Strong dimensional stability.

Good electrical conductivity, temperature resistance, light shielding, and shielding performance.

Product Structural Diagram of Mylar Aluminum Tape

Main Applications Include:

-

- Electromagnetic interference suppression for electronic devices such as computers, transformers, cell phones and navigation systems.

- Thermal conduction and dissipation for electronic appliances like mobile phones, computers, televisions, etc.

- Sealing of pipe joints for central air conditioning, extractor hoods, refrigerators, and water heaters.

- Insulation for refrigerator and air conditioning ducts.

- Electromagnetic shielding for wire and cable materials.”

|

|

|

Pipe insulation(Mylar Aluminum Tape) |

Transformer shield (D-Aluminum Tape) |

|

|

|

Pipe seal(Mylar Aluminum Tape) |

NFC Film(Nano Carbon Aluminum Tape) |

|

|

|

Covering protection(S-Aluminum Tape) |

Covering protection(S-Aluminum Tape) |

|

|

|

Gas stove anti-fouling(S-Aluminum Tape) |

Heat Dissipation(Nano Carbon Aluminum Tape) |

Nanocarbon Aluminum Foil Tape Product Parameter Table

Test items Test method Unit Product Type P1305 P1307 P13085 P1310 P1313 P1315 Color Visual inspection – black black black black black black Type of glue – – Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Base material – – Nano carbon aluminum foil Nano carbon aluminum foil Nano carbon aluminum foil Nano carbon aluminum foil Nano carbon aluminum foil Nano carbon aluminum foil Substrate thickness ASTM D-3652 mm 0.025 0.02 0.05 0.05 0.05 0.1 Total thickness ASTM D-3652 mm 0.05 0.07 0.085 0.1 0.13 0.15 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 10(4) 12(4.8) 12(4.8) 15(6) 15(6) 15(6) Room temperature retention GB/T4851-1998 H 8 12 12 24 24 24 Thermal conductivity of base course ASTMD5470 W/mk 200 200 200 200 200 200 Thermal conductivity of composite layer ASTMD5470 W/mk 300~600 300~600 300~600 300~600 300~600 300~600 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120

S-Aluminum Foil Tape Product Parameter Table

Test items Test method Unit Product Type P0604 P0606 P0607 P0609 P0614 P0615 Color Visual inspection – Silvery Silvery Silvery Silvery Silvery Silvery Type of glue – – Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Base material – – Aluminum foil Aluminum foil Aluminum foil Aluminum foil Aluminum foil Aluminum foil Substrate thickness ASTM D-3652 mm 0.015 0.025 0.025 0.05 0.05 0.1 Total thickness ASTM D-3652 mm 0.04 0.06 0.07 0.09 0.14 0.15 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 10(4) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 15(6) Room temperature retention GB/T4851-1998 H 12 12 12 12 12 24 Surface resistance (horizontal, adhesive surface) GB/T 1410-2006 mΩ ≤120 ≤120 ≤120 ≤120 ≤120 ≤120 Surface resistance (vertical) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120

D-Aluminum Foil Tape Product Parameter Table

Test items Test method Unit Product Type P0606D P0607D P0609D P0610D P0614D P0615D Color Visual inspection – Silvery Silvery Silvery Silvery Silvery Silvery Type of glue – – Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Base material – – Aluminum foil Aluminum foil Aluminum foil Aluminum foil Aluminum foil Aluminum foil Substrate thickness ASTM D-3652 mm 0.025 0.025 0.05 0.05 0.1 0.1 Total thickness ASTM D-3652 mm 0.06 0.07 0.09 0.1 0.14 0.15 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 15(6) Room temperature retention GB/T4851-1998 H 12 12 12 12 12 24 Surface resistance (horizontal, adhesive surface) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Surface resistance (vertical) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120

Mylar Aluminum Tape Product Parameter Table

Test items Test method Unit Product Type P0905 P09055 P0907 P0908 P0909 P0912 Color Visual inspection – Silvery Silvery Silvery Silvery Silvery Silvery Type of glue – – Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Acrylate adhesive Base material – – Mylar aluminum foil Mylar aluminum foil Mylar aluminum foil Mylar aluminum foil Mylar aluminum foil Mylar aluminum foil Substrate thickness ASTM D-3652 mm 0.02 0.025 0.038 0.05 0.05 0.075 Total thickness ASTM D-3652 mm 0.05 0.055 0.07 0.08 0.09 0.12 Peel strength(180°) ASTM D-3330 N/inch(N/cm) 10(4) 12(4.8) 12(4.8) 12(4.8) 12(4.8) 15(6) Room temperature retention GB/T4851-1998 H 12 12 12 12 12 24 Surface resistance (aluminum foil surface) GB/T 1410-2006 mΩ ≤100 ≤100 ≤100 ≤100 ≤100 ≤100 Long term temperature resistance GB∕T 32368-2015 ℃ 80 80 80 80 80 80 Short term temperature resistance GB∕T 32368-2015 ℃ 120 120 120 120 120 120