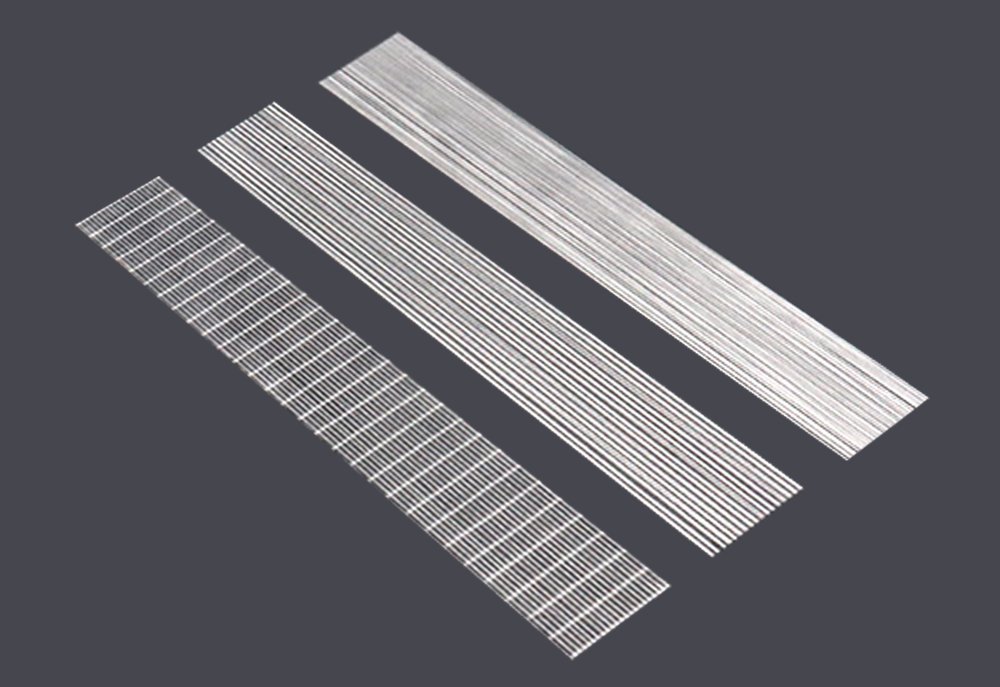

Due to historical differences in industrial development, the global adhesive tape market has been dominated by large companies such as 3M and Tesa, primarily based in the US. Currently, in the field of fiberglass tape, foreign brands such as 3M and Tesa have a higher market share, while domestic brands have a lower market share. You-San aims to provide an economical and technically superior alternative to 3M and Tesa products with our complete research and development team and series of fiberglass tape products, including unidirectional fiberglass tape (striped fiberglass tape), bidirectional fiberglass tape (grid fiberglass tape), and double-sided fiberglass tape. All of our products are independently researched and developed and can replace foreign brand fiber tape with a price advantage to achieve domestic production of tape.

Our team of experts has developed fiber tapes made from the highest quality materials and the latest manufacturing techniques to deliver superior performance and durability. By utilizing advanced adhesives and special coatings, our tapes possess high tensile strength and superior bonding properties, outperforming many of the products currently available in the market. Furthermore, the best part of our fiber tape is our price. Our state-of-the-art technology and manufacturing processes allow us to offer our products at a much more competitive price point than 3M and Tesa’s products. This means that you do not have to compromise on quality and performance, while saving a significant amount of money in the process.

Let’s take a look at what fiberglass tape is. fiberglass tape is a specialty tape made of glass fiber composite PET/PP film substrate. It is also called fiber glass tape or filament tape. Its main features include high tensile strength, excellent wear resistance, strong load-bearing capacity, high peel strength, and no residue.

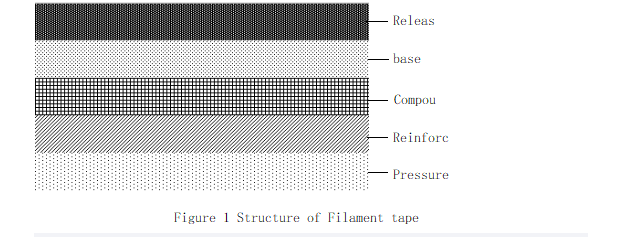

fiberglass tape is generally composed of release liner, substrate, composite adhesive, reinforcing fiber, pressure-sensitive adhesive, etc. (as shown in Figure 1 below). Commonly used substrates include PET film, PVC film, BOPP film, and various papers that have been surface treated.

Fiber-reinforced adhesive tape can be classified into three types based on its tensile strength: standard tensile strength, medium tensile strength, and high tensile strength. Their tensile strengths are as follows: standard tensile strength is 160-290N/cm, medium tensile strength is 300-450N/cm, and high tensile strength is 460-850N/cm.

The main application industries are as follows:

fixation |

heavy object |

|

|

|

model pasting and fixation |

wire fixation |

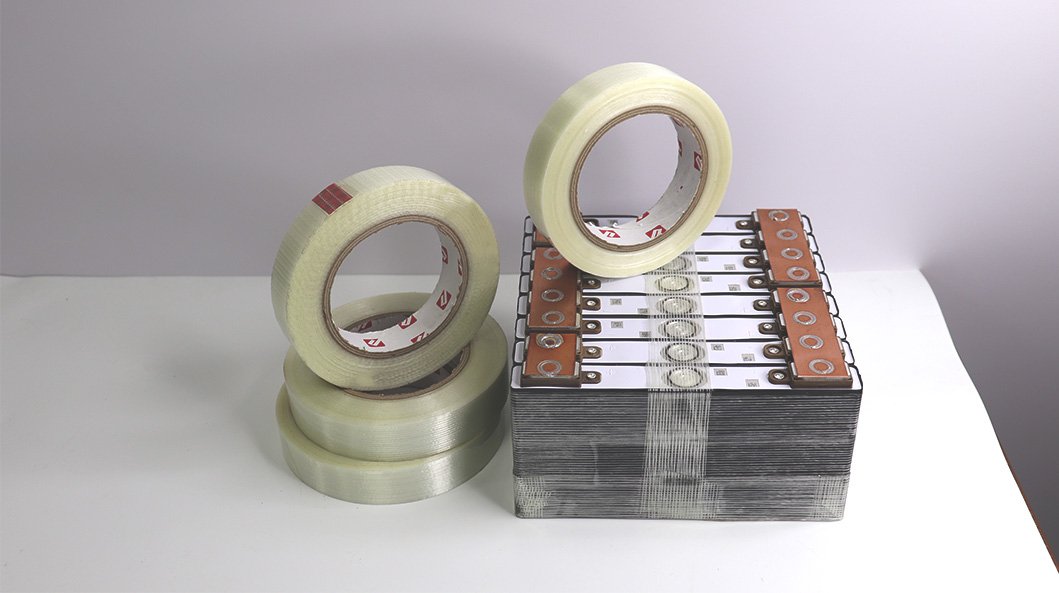

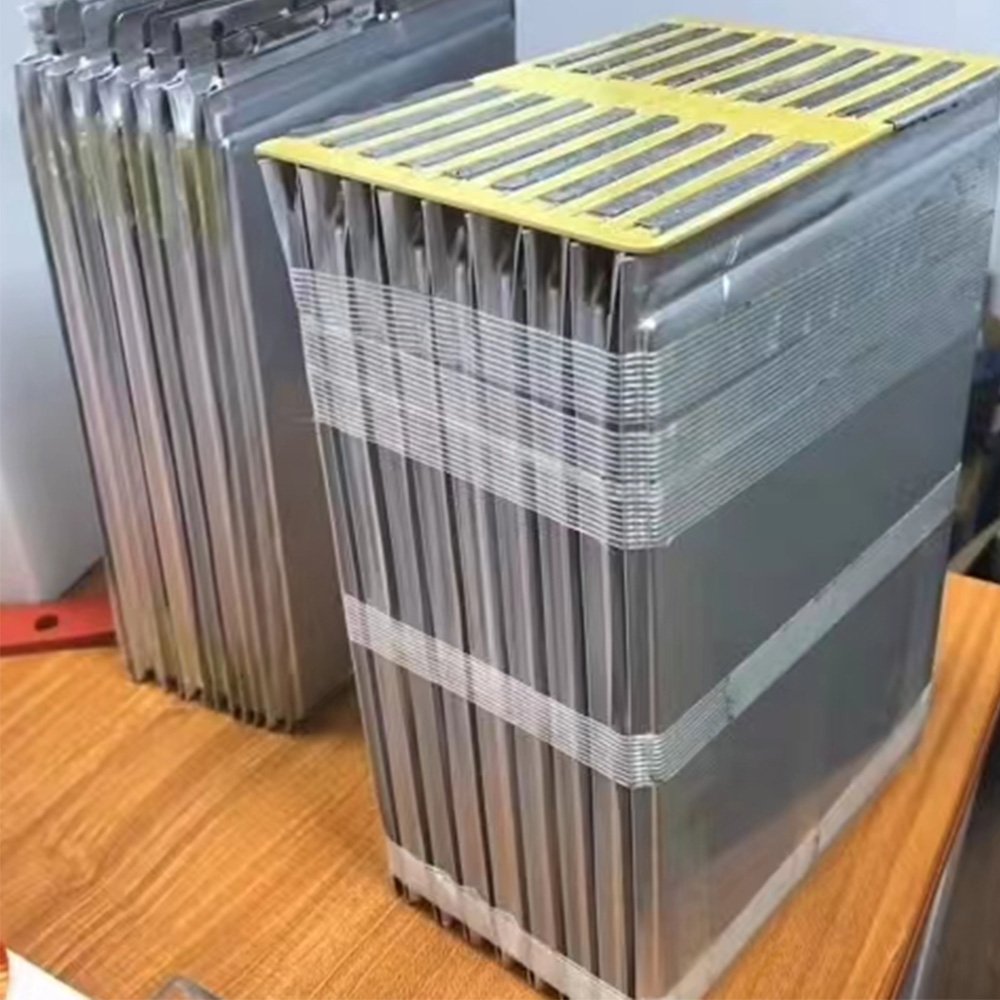

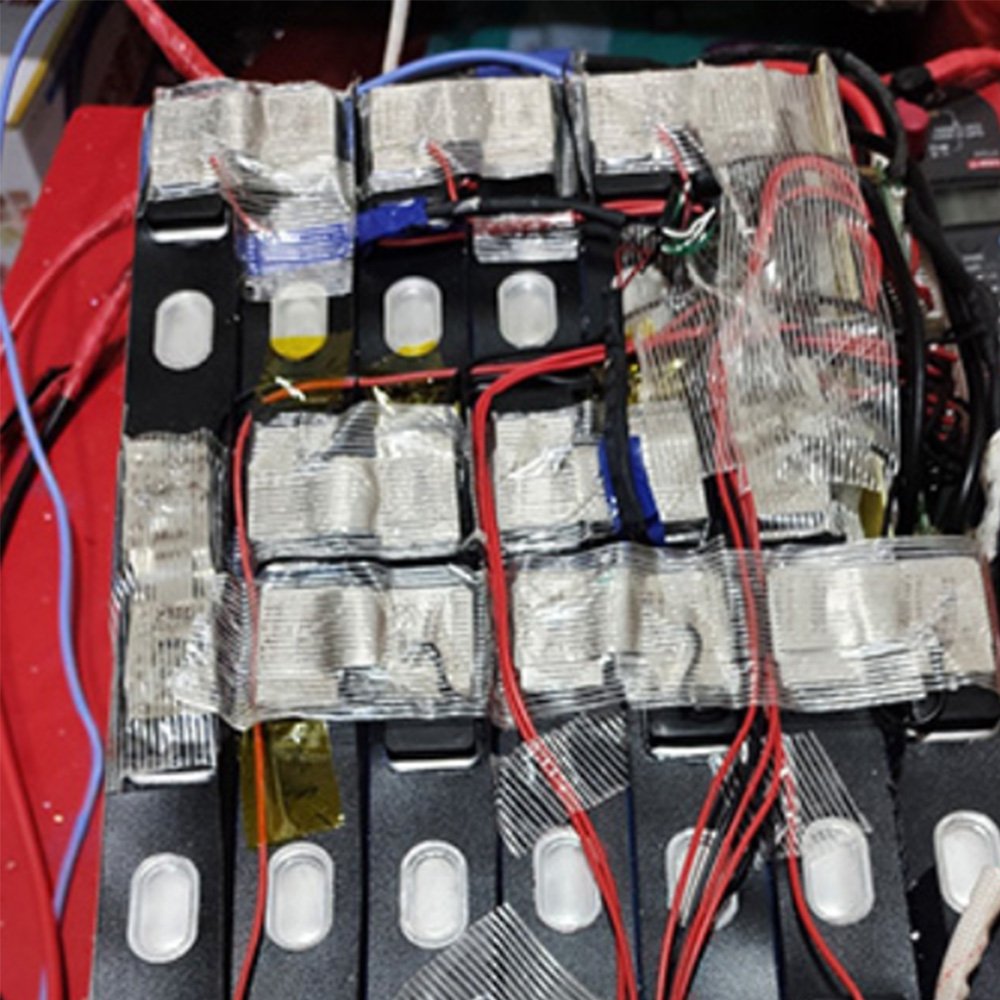

lithium battery fixation |

lithium battery binding |

lithium battery assembly |

Heavy duty application |

Performance of Yousan Filament tape

project Company Test method Striped Filament tape Mesh Filament tape Double sided Filament tape P1212 P1214 P1216 P1218 P1201W P1208 colour – Visual inspection transparent transparent transparent transparent transparent yellow base material – – PET PET BOPP PET PET Grating paper Colloidal system – – rubber rubber rubber rubber Hot melt adhesive Hot melt adhesive Total thickness mm ASTM D-3652 0.114 0.137 0.155 0.173 0.13 0.3 Peel strength (180 °) N/inch(N/cm) ASTM D-3330 12.7(5.0) 14.0(5.5) 12.7(5.0) 10.7(4.2) 18(7.1) 22(8.7) Retentive force h ASTM D-3654 ≥24 ≥24 ≥24 ≥24 ≥24 ≥24 tensile strength N/inch(N/cm) ASTM D-3759 635(250) 965(380) 762(300) 1346(530) 550(216) 300(118) elongation % ASTM D-3759 4 4 4.5 4.5 4 5 High and low temperature resistant residual rubber ℃ GB∕T 32368-2015 (-10)/80 (-10)/80 (-10)/80 (-10)/80 (-5)/60 (-5)/60 Remarks: The above test results are only typical values, not guaranteed values. In case of new knowledge and experience, Yousan will modify this information accordingly without further notice. You-San strongly recommends that customers conduct independent tests before using the product to understand the applicability of the product. You-San will not be responsible for any damage or injury caused by the use of the product.

Application for each model are as follows:

Striped Filament Tape:

P1212 (standard strength)

①Temporary fixation of moving parts in household appliances

②Lithium battery assembly binding

③Electrical circuit fixation

④Model pasting and fixation of aviation model accessories and toy structural parts

⑤Electrical circuit fixation

P1214 (medium strength):

①Temporary winding of household appliances

②Furniture transportation and fixation

③Sealing of heavy cardboard boxes

④Electrical safety transportation fixation

⑤Lithium battery binding fixation

P1216 (medium strength):

①Sealing of metal coils

②Medium-weight cylindrical/sheet-shaped items

③Electrical safety transportation fixation

④Heavy object transportation and fixation

⑤Lithium battery binding fixation

P1218 (high strength):

①Bundling of large heavy objects

②Wrapping and fixation of bridge wire ropes

③Safety transportation fixation of large electrical appliances

④Splicing during the production of large metal plates

⑤Transportation and fixation of large furniture

Mesh Filament Tape:

P1201W

①Heavy cargo strapping

②Enhancement of sea shipping boxes

③Pallet fixation

④Temporary fixation of furniture during transportation

Double-Sided Adhesive Filament Tape:

P1208:

①Rubber door and window seal strip fitment

②Foam fitment

③Automotive moving parts fitment

④Floor sound insulation, non-woven fabrics fitment.

temporary winding and fixation of coil materials

temporary winding and fixation of coil materials temporary fixation of electrical appliances

temporary fixation of electrical appliances