PET, which stands for polyethylene terephthalate, is a type of polyester. The first manufacturer (DuPont) to produce PET film registered it as “Mylar,” which has resulted in “Mylar tape” almost becoming synonymous with PET tape.

Mylar tape possesses excellent electrical and physical properties. It is generally around 50-80μm thick. Mylar tape is primarily used as an insulating wrapping layer for coils, transformers, and electric motors. These applications require tape with a small thickness yet high electrical and tensile strength, making Mylar tape with a thickness below 100μm the preferred choice.

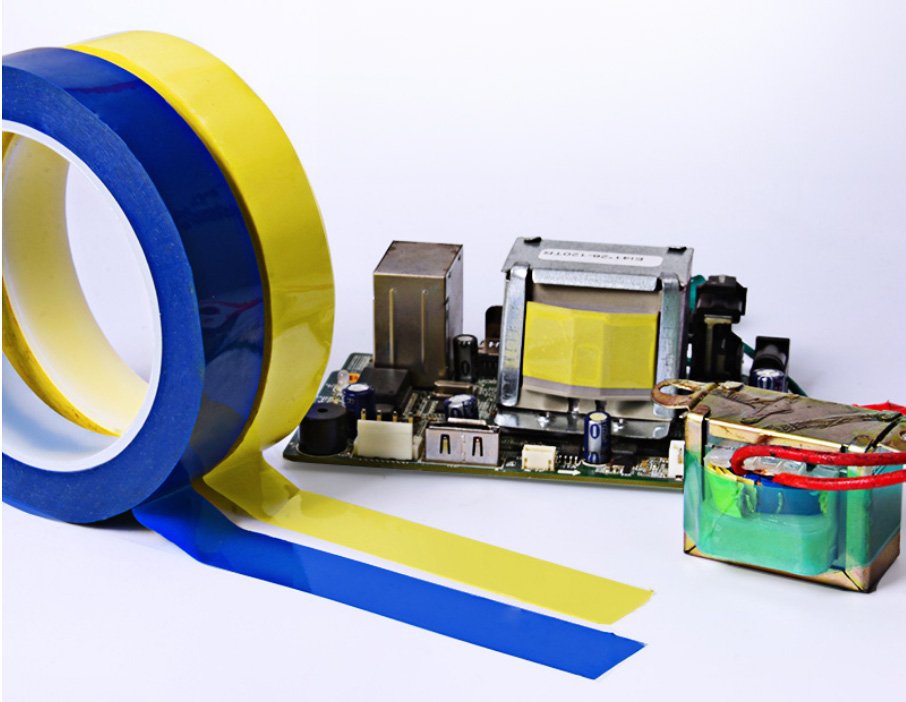

You-san Technology Mylar tape products are polyester tapes with high-performance PET film as the base material and coated with acrylic pressure-sensitive adhesive. They are mainly used for:

①Wrapping and bundling capacitors and wire coils

②Insulating and covering transformers and motor windings

③Insulation and high-temperature resistance in electronic and electrical applications

④High-voltage isolation in the circuit boards of switch mode power supplies

⑤Bundling between protective plates and battery cells in flexible lithium-ion batteries.

Transformer |

Capacitor |

Coil |

Motor |

Mylar tape has numerous advantages, including excellent insulation performance and good flame retardant properties, which make it a viable alternative to foreign brands.

Mylar Tape Product Specification Table

Item Testing Method Units Product Number P16055 P1608 Color Visual Inspection – White, black, light yellow, dark yellow, blue, red, green, transparent White, black, light yellow, dark yellow, blue, red, green, transparent Adhesive – – Acrylic Acrylic Backing – – PET PET Backing Thickness ASTM D-3652 mm 0.025 0.05 Total Thickness ASTM D-3652 mm 0.055 0.08 Peel Strength(180°) ASTM D-3330 N/inch(N/cm) 8(3.2) 8(3.2) Tensile Strength ASTM D-3759 N/inch(N/cm) 87.5(35) 225(90) Elongation At Break ASTM D-3759 % 70 70 Breakdown Voltage ASTM D-1000 KV ≥3.5 ≥3.5 Insulation Resistance ASTM D-1000 Ω 1×1012 1×1012 Short-Term Temperature Resistance GB∕T 32368-2015 ℃ 150 150 Long-Term Temperature Resistance GB∕T 32368-2015 ℃ 120 120 Flame Retardant Grade UL-510 – UL-510 UL-510

Comparison Table of You-san Products and 3M Product Specifications

Product Code Thickness Base Color Backing Thickness Adhesive Peel Strength(N/cm) Insulation Resistance UL510 Tensile Strength(N/cm) Elongation At Break 3M 1350F-1 0.063mm PET Yellow, White, Black 0.025mm Acrylic 3.3 >106 UL510 Certificate 44 100% P16055 0.055mm PET White, black, light yellow, dark yellow, blue, red, green, transparent 0.025mm Acrylic 3.2 >106 UL510 35 70% 3M 1350F-2 0.088mm PET Yellow, White, Black 0.05mm Acrylic 3.3 >106 UL510 Certificate 88 110% P1608 0.08mm PET White, black, light yellow, dark yellow, blue, red, green, transparen 0.05mm Acrylic 3.2 >106 UL510 90 70%

Note: Technical parameters for 3M products are sourced from 3M TDS technical data.