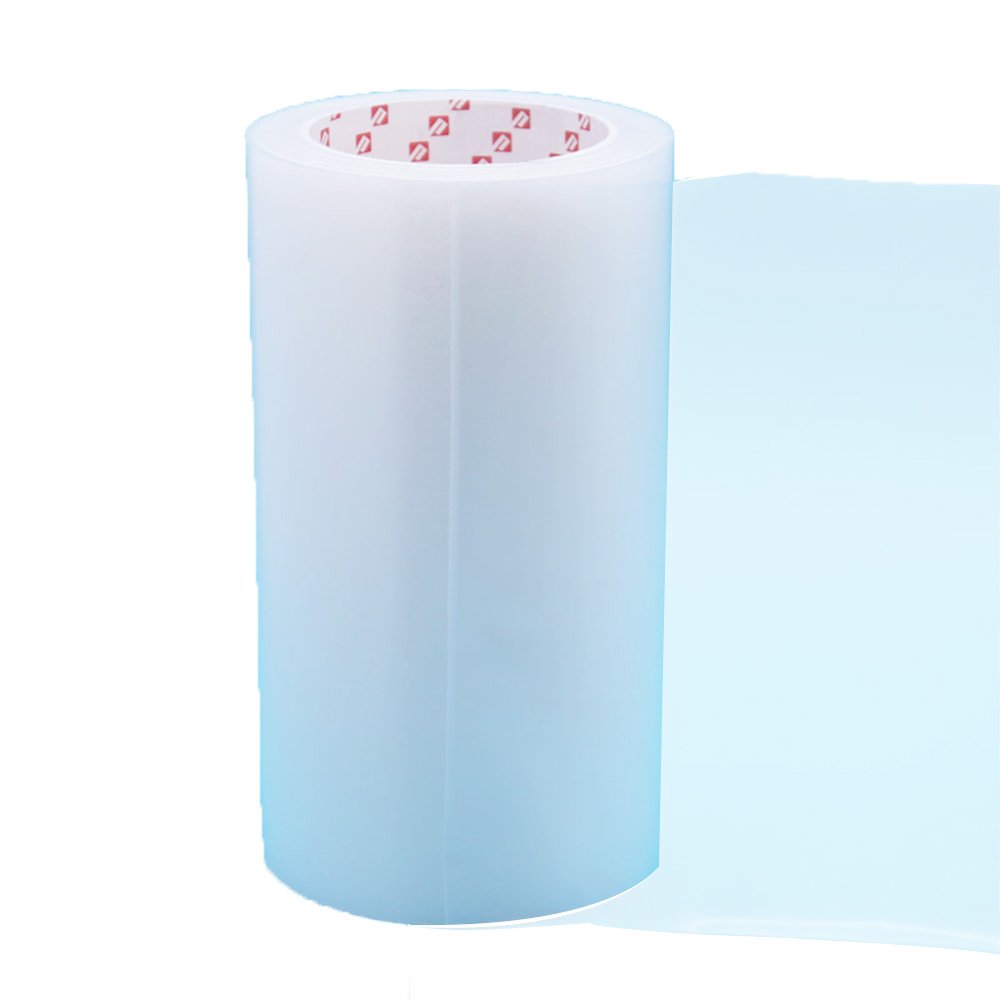

What is CPP Protective Film?

CPP Protective Film is a material that protects surfaces that are susceptible to damage: minor or moderate abrasions to scratches and more.

CPP Protective Film is well known for its versatility. CPP is gaining popularity as a more appealing packaging material than polyethylene in many areas because it has higher clarity and better heat resistance.

The qualities of the CPP Protective Film can be customized to fit specific packaging, performance, and processing needs. CPP has stronger tear and impact resistance, cold temperature performance, and heat-sealing qualities than other plastics. CPP films can also be printed with flexographic or rotogravure methods.

Protective films were originally developed with military applications in mind.

Back in the 60th years old, U.S Department of Defense realized that their helicopter blades could not escape the damage caused by debris in the air. This problem eventually inspired the creation of a protective layer that was designed to be transparent, lightweight, and strong enough to prevent damage to the military equipment in use.

These protective layers, or “helicopter tape,” evolved into the protective film we see on modern-day vehicles.

Today, we’ll discuss the protective film benefits we’ve seen in industries we’ve worked with and how it could benefit your future projects.

What is CPP Protective Film Made of?

Protective film serves many different purposes and industries, so its composition depends on the part application.

Here are a few specific types of materials, primarily plastic, that are commonly used to create protective film:

Low-density polythene films have enhanced elasticity and flexibility, and are generally low in weight

Polyvinyl chloride is sleek with relatively higher levels of elasticity, making it an ideal option for metal surface protection

Polypropylene is less elastic and holds firm even in higher temperatures

Polyolefin works exceptionally well with glass or painted metal, and specific variants are used for packaging

Co-extruded, low-density polythene provides a higher level of protection by using layering techniques

Paper is generally used to protect against very low-impact damage

Types of CPP Protective Film

Protective film comes in a variety of styles, each specifically designed for an application, and they generally vary according to thickness, material, and adhesive strength.

These are two of the most common types of CPP Protective Film you’ll encounter:

1. SURFACE PROTECTIVE FILM

A high-quality surface protective film can easily be applied and removed while providing a sleek finish to the surface it is used on. These films protect vulnerable surfaces: glass, commercial glazing, plastic, stone, brick, granite, marble, and more.

Industries with a focus on manufacturing and distribution of packaged products generally find themselves with a need for this kind of protection. However, cutting these films into appropriate shapes to fit various surfaces becomes difficult. Additionally, the user has to ensure minimal bubbling upon application, which often requires a professional’s expertise in surface protection films.

2. PROTECTION FILM FOR PAINTED SURFACES

Paint protection films generally have a higher resistance toward impact. Variants such as the clear paint protection film (PPF) have “self-healing” properties that allow them to return to their natural shape after impact or abrasions.

These kinds of films are usually made from elastomeric polymer, providing elasticity to the film. They’re traditionally invisible, allowing the object to maintain its aesthetic value while adding a level of protection. That’s why common uses include cell phones, electronics, cars, airplanes, and other equipment.

While PPF is not bulletproof, it does provide superior protection against rock chips and other environmental contaminants. It is also chemical resistant, allowing you to wash or clean your equipment without fearing the loss of adhesive or the inability to execute maintenance practices.

Yousan TAPE is a professional industrial CPP Protective Film manufacturer with 18 years of production experience and a leading position in China. Their professional research team can produce compliant products that meet various testing regulations.

Yousan TAPE uses quality materials in their manufacturing process to ensure the durability and longevity of their CPP Protective Film. This ensures optimal performance even in harsh environmental conditions, making it suitable for both indoor and outdoor applications.

By choosing Yousan Tape China, you can be sure that you are working with a reputable manufacturer, contact us today for all your CPP Protective Film needs.