What is aerogel?

Aerogel is a special type of gel in which gas replaces the liquid in the gel structure without fundamentally altering its network or volume. Due to its semi-transparent color and extremely light weight, it is sometimes referred to as “solid smoke” or “frozen smoke”. The internal structure of aerogel is unique, and it exhibits exceptional thermal insulation properties. Aerogel materials are characterized by their low density, high surface area, and high porosity. They possess special thermal, optical, electrical, and acoustic properties, including high temperature resistance, low thermal conductivity, low refractive index, and low sound propagation speed. Thanks to its unique structure, aerogel surpasses traditional insulation materials like silica-alumina and glass wool in terms of insulation performance, relying on the absence of convection, infinite blocking effect, and infinitely long tortuous path effect. Therefore, aerogel is an excellent material for applications requiring extremely high insulation requirements, as well as lightweight, stability, and good performance.

According to the different materials, aerogels can be classified into four categories: inorganic aerogels, organic aerogels, hybrid aerogels, and composite aerogels. Each type has specific properties and finds applications in downstream sectors such as aerospace, industrial equipment, petrochemicals, and building pipelines.

Among them, SiO2 aerogel, as an excellent lightweight nanoporous amorphous solid material with exceptional fireproof and thermal insulation properties, is currently the most mature product in terms of production technology and commercial applications. It possesses outstanding properties such as low density, low thermal conductivity, high porosity, and high specific surface area. SiO2 aerogel has wide application prospects in areas such as pipeline insulation, thermal insulation coatings, energy-saving glass, pipeline corrosion protection, adsorption catalysis, and more.

Here are the characteristics of aerogels:

1.Low thermal conductivity.

2.High temperature resistance.

3.Lightweight and thin products.

4.Highly hydrophobic.

5.Excellent dimensional stability.

6.Lightweight.

7.Moderate

8.flexibility

What is aerogel insulation film?

Aerogel films coated with acrylic ester can be used to produce aerogel insulation films, which have both insulation and adhesive properties. They can be directly applied and adhered to the surface of components to achieve insulation effects.

Aerogel insulation pads are a type of composite insulation material based on silica aerogel and ceramic fiber substrate. They effectively block heat transfer between heat-generating parts and the equipment casing.

Aerogels have prominent advantages and are widely used in high-end engineering and equipment construction fields. On one hand, aerogels have excellent product performance and low density, making them highly suitable for most insulation and thermal insulation applications. However, the production of aerogels requires high barriers, substantial equipment investment, and challenging process control. Therefore, the cost of aerogels is relatively high, and they are mainly used in scenarios where engineering and equipment demand high application requirements and performance.

The lower the operating temperature of batteries, the longer their lifespan. The insulation cotton on the battery pack cover is a new type of space-saving, energy-efficient, reflective insulation coating with high efficiency, thin layer, thermal insulation, decoration, waterproof, fireproof, corrosion-resistant, and insulation capabilities. The coating forms a three-dimensional network hollow structure composed of closed microbeads on the surface of objects. The nano hollow ceramic microbeads are connected together, forming insulated insulation units.

The insulation level can reach R-30.1, and the thermal reflectance is above 90%, allowing for significant reflection of infrared radiation and preventing heating of objects by infrared rays. The thermal conductivity of the coating is 0.03W/m·K, effectively suppressing the radiant heat and heat conduction from the sun and infrared radiation. The insulation and thermal inhibition efficiency can reach about 90%. It is a low-density and ultra-lightweight insulation material.

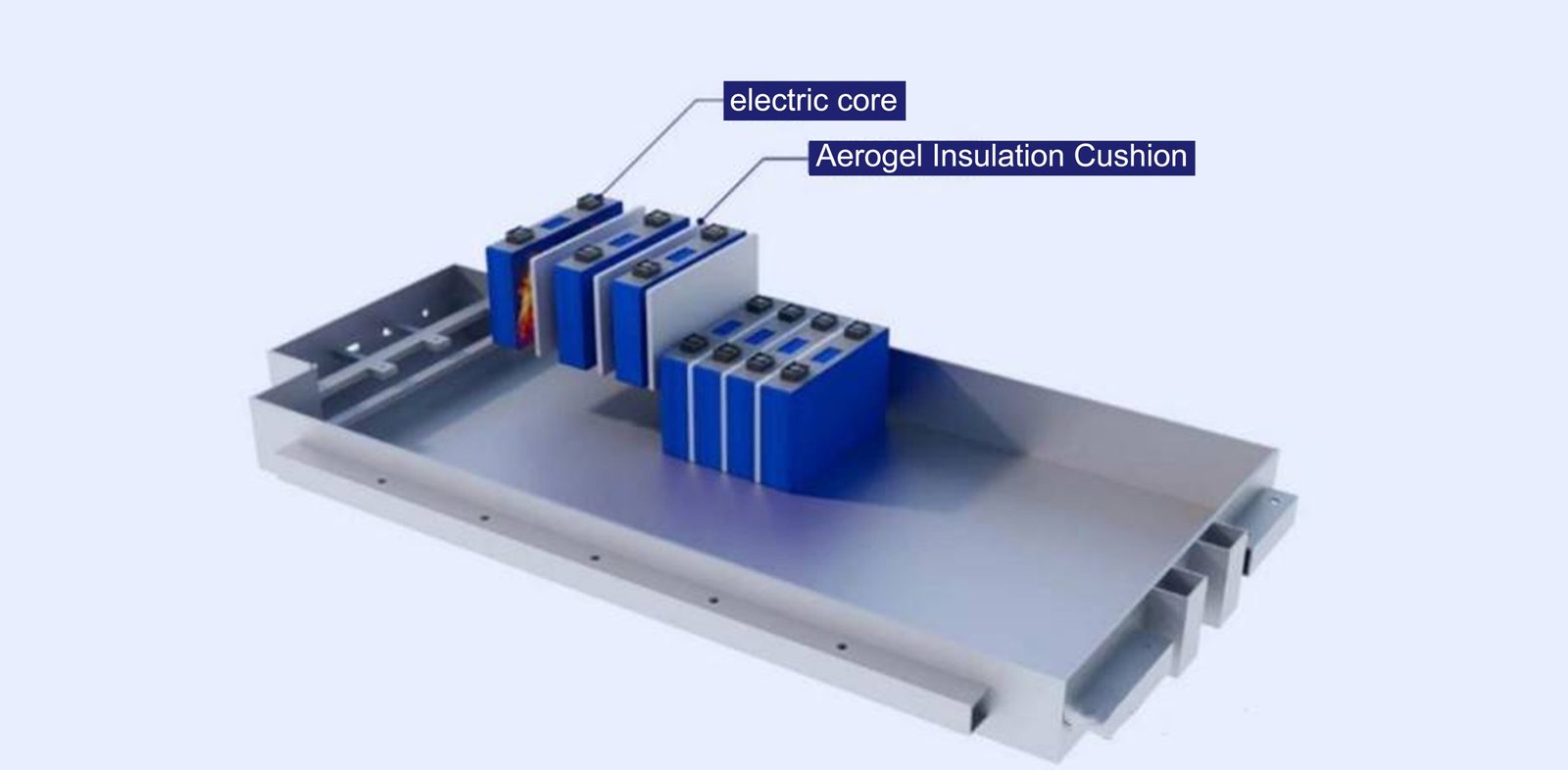

Currently, lithium-ion batteries are the primary power source for new energy vehicles. However, thermal runaway under extreme conditions poses a significant safety hazard to the power batteries of these vehicles. In the field of new energy vehicles, aerogel insulation materials are mainly used for insulation and flame retardation between the battery cells, insulation and shock absorption between the module and the casing, external cold protection layer of the battery pack, and high-temperature insulation layer. This allows for better temperature control and electrical management of the batteries, significantly reducing the likelihood of thermal runaway. Compared to traditional IXPE insulation foams, aerogel insulation pads have significant advantages in terms of operating temperature, thermal conductivity, flame retardancy, and other key indicators.

What’s the use of aerogel?

The increasing demand for insulation materials is driven by the safety requirements of batteries. As the safety performance requirements for battery packs continue to rise, aerogel, as a higher-end insulation material, can significantly enhance the safety performance of batteries. Therefore, it has been increasingly used in battery applications. In particular, lithium-ion batteries with higher compaction density and longer range require higher-end aerogel materials in the production process to meet safety requirements. The penetration rate of aerogel materials is continuously increasing in this regard. Additionally, there is also gradual penetration into other areas such as lithium iron phosphate power batteries and energy storage batteries. On one hand, with the increasing shipment volume of downstream batteries, the application of aerogel as a PACK insulation material will also increase. At the same time, with cost control and increased penetration rate, the proportion of aerogel application will further expand. It is expected that the rapid growth of the demand for aerogel will be driven by the new energy battery industry, making it another potential market apart from the construction sector.

The battery insulation pad is composed of a core material such as pre-oxidized silk or other types of aerogels, encapsulated with polymer (PET, PI) film or flame retardant coating through heat pressing or coating composite. It has excellent insulation and cushioning functions and is mainly used for thermal protection between the power lithium battery cells, preventing thermal runaway of the cells and significantly improving the driving experience of new energy vehicles.

When one of the battery cells experiences thermal runaway, the aerogel insulation pad can block the heat transfer to adjacent cells, preventing heat diffusion and avoiding the domino effect of thermal runaway in new energy power battery cells. The aerogel insulation pad also has good compression performance and can act as a cushioning material between the cells, accommodating the expansion and contraction changes of the cells during charging and discharging.

When applied in the lithium-ion power battery module, the low thermal conductivity of the aerogel insulation sheet can effectively inhibit the rapid heat dispersion during high-rate charging and discharging of the cells. When a cell experiences thermal runaway, it can provide insulation to delay or prevent accidents. In the event of cell overheating and combustion, the aerogel insulation board with Class A non-flammable performance can effectively block or delay the spread of fire, providing sufficient time for evacuation. Therefore, aerogel insulation sheets play a significant role in improving the safety performance of new energy vehicle power battery packs.

By adding aerogel insulation pads between battery modules, the thermal diffusion can be effectively suppressed and the occurrence of accidents can be delayed in the event of cell thermal runaway. On the other hand, aerogel insulation pads have the characteristics of low thermal conductivity, good insulation effect, Class A fire resistance, and light weight. When applied to battery pack insulation, they can ensure the performance of the battery in a low-temperature environment and save valuable space in the limited space of the battery pack.

Aerogel products combine nano-aerogel with base materials such as glass fibers and ceramic fibers. This perfect combination retains the excellent properties of aerogel, such as lightweight and insulation, while also giving it flexibility and toughness. These aerogel products have additional characteristics including long service life, strong insulation performance, high fire resistance, and excellent mechanical properties. They are widely used in fields such as military aerospace, thermal power networks, petrochemicals, new energy vehicles, power batteries, rail transportation, consumer electronics, and textiles.