Double-sided Transfer tape is made directly from acrylic adhesive. The tape is transparent in color and commonly available in thicknesses ranging from 0.06 to 0.13 millimeters. It has good light transmittance. The adhesive part of the no-substrate double-sided tape is composed of acrylic ester adhesive, which provides excellent adhesion, prevents detachment, and exhibits excellent water resistance. It has good workability, temperature resistance, dimensional stability, thermal stability, and chemical stability. It has good initial tack and holding power, making it suitable for a wider range of temperatures and harsh environments. It is commonly used for panel bonding, shock-absorbing foam bonding, door and window seals, and bonding of metals and plastics, among other applications.

The Features of Double-Sided Transfer Tape

Substrate-less design: The unique substrate-less design of the double-sided tape allows the acrylic adhesive to be directly molded, creating a thin and lightweight product. This design enhances the tape’s flexibility and adhesion, enabling it to conform to various curved and irregular surfaces and providing excellent bonding performance.

High adhesive strength: The substrate-less double-sided tape exhibits exceptional adhesive strength, quickly and securely bonding two objects together. It offers strong and long-lasting adhesion, even under extreme temperature and humidity conditions. Its high adhesive strength makes it an ideal choice for applications that require strong bonding.

Transparency: The substrate-less double-sided tape’s transparency sets it apart in applications requiring light transmission, such as attachment beneath screens of smartphones, tablets, and computers. This ensures both the bonding effectiveness and maintains the smoothness and stability of the bonded objects.

Good temperature resistance: The substrate-less double-sided tape demonstrates excellent temperature resistance, allowing it to be used in both high and low temperature environments. It can maintain stable bonding performance under various extreme conditions, meeting the requirements of various industrial and commercial applications.

Aging resistance: The substrate-less double-sided tape possesses good aging resistance, maintaining its performance during prolonged use. Even when exposed to UV radiation, oxygen, or other environmental factors, its adhesive strength and other properties can be maintained for a considerable duration.

Environmental friendliness: The adhesive and other materials used in substrate-less double-sided tape are generally environmentally friendly, posing no harm to human health or the environment. Many types of substrate-less double-sided tape have obtained certification according to environmental standards like the EU’s REACH certification. Additionally, the production process of our substrate-less double-sided tape emphasizes energy conservation and resource recycling to minimize environmental impact.

Die-cutting: The substrate-less double-sided tape is easy to process and use. It can be easily cut into different shapes and sizes to meet various bonding requirements. Whether applied in different locations, it can fulfill specific usage needs by selecting the appropriate shape.

The Application of Double-Sided Transfer Tape

The Double-Sided Transfer Tape has a wide range of applications and can be used on various materials and surfaces, such as plastic, metal, and glass. It is widely used in industries including nameplate manufacturing, plastics, automotive, mobile phones, electronics, sponge, rubber, signage, paper products, toys, and more. It delivers excellent bonding performance and temperature resistance. Here are some specific applications:

|

|

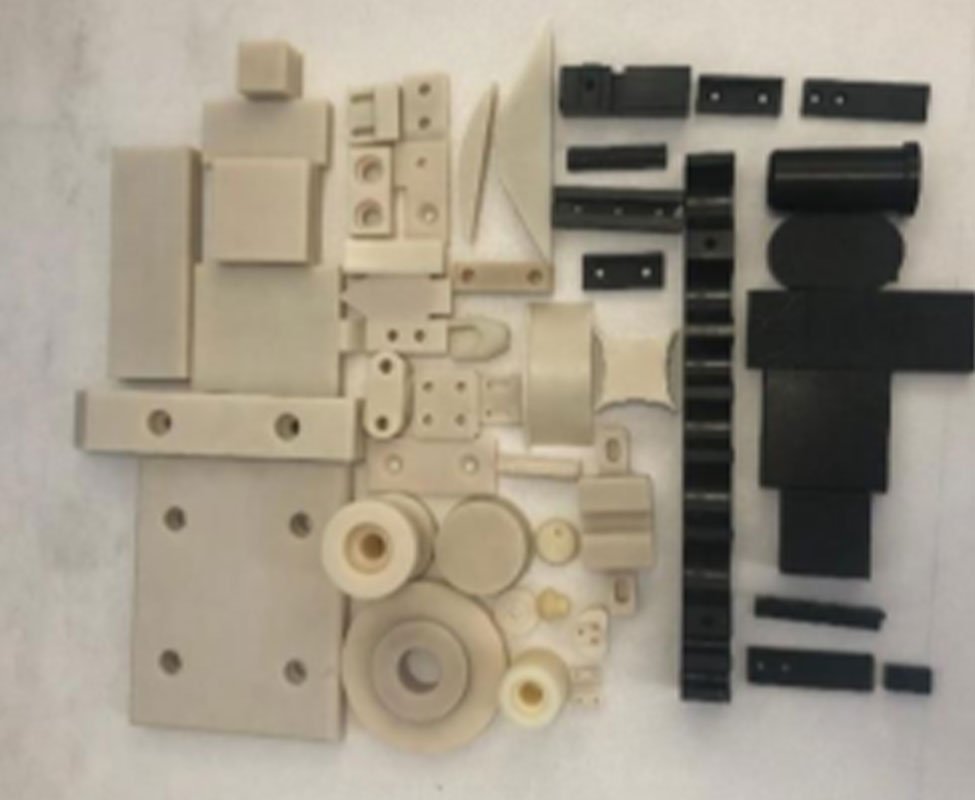

| Attachment of plastics | Bonding of metals |

|

|

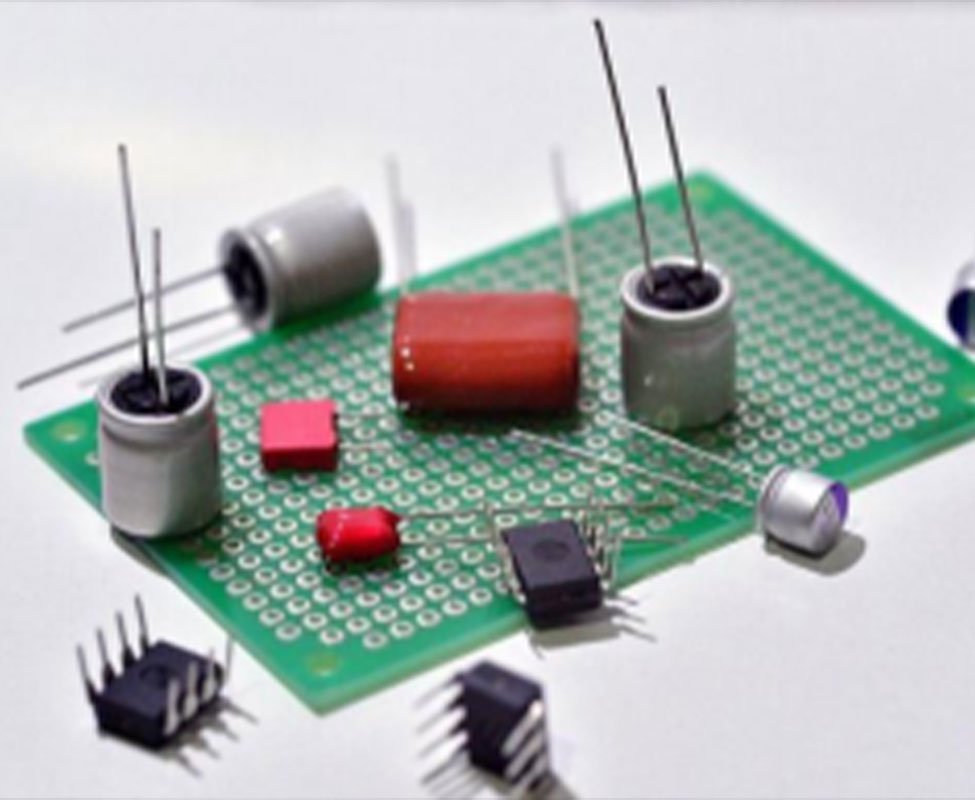

| theBonding of flexible printed circuit boards | Assembly of electronic instrument components |

|

|

| Attachment of shock-absorbing foam | Adhesion of display screen lenses |

1.Attachment of shock-absorbing foam: It is used in places that require shock absorption or sound insulation, such as attaching seals to doors and windows to ensure their sealing.

2.Bonding of flexible printed circuit boards: The flexible and conformable substrate-less double-sided tape is used to bond and secure materials that need to be bent or flexed.

3.Bonding of metals and plastics: The substrate-less double-sided tape can be used for bonding metals and plastic materials.

4.Adhesion of display screen lenses: The substrate-less double-sided tape offers high adhesion and waterproofing properties, ensuring a tight bond between the lens and the display screen, minimizing the risk of detachment.

5.Assembly of household appliances and electronic instrument components: The substrate-less double-sided tape can be used for assembling components in household appliances and electronic instruments.

Product Code Color Total Thickness [um] Backing Adhesive Initial Tack[mm] 180°Peel Strength [N/inch] Retentivity

[hour]Long-Term Temperature Resistance

[℃]Short-Term Temperature Resistance

[℃]P3112A Translucent 120 Tissue Acrylic ≤100 ≥20 48 120 150 P3114A Translucent 140 Tissue Acrylic ≤100 ≥20 48 120 150 P3115A Translucent 150 Tissue Acrylic ≤100 ≥20 48 100 150 P3115A+ Translucent 150 Tissue Acrylic ≤100 ≥18 48 150 180 P3116A Translucent 160 Tissue Acrylic ≤100 ≥20 48 120 150 P3115AB Translucent 150 Tissue Acrylic ≤100 ≥20 48 100 150 P3105H Translucent 50 Tissue Acrylic ≤100 ≥9 24 80 120 P3110H Translucent 100 Tissue Acrylic ≤100 ≥11 24 80 120 P3112H Translucent 120 Tissue Acrylic ≤100 ≥13 24 80 120 P3114H Translucent 140 Tissue Acrylic ≤100 ≥15 24 80 120 P3116H Translucent 160 Tissue Acrylic ≤100 ≥16 24 80 120 P3110B Black 100 Tissue Acrylic ≤100 ≥11 24 80 120 P3112B Black 120 Tissue Acrylic ≤100 ≥13 24 80 120 P3114B Black 140 Tissue Acrylic ≤100 ≥15 24 80 120 P3116B Black 160 Tissue Acrylic ≤100 ≥16 24 80 120 P3112N Translucent 120 Tissue Acrylic ≤100 ≥12 24 120 150 P3114N Translucent 140 Tissue Acrylic ≤100 ≥14 24 120 150 P3116N Translucent 160 Tissue Acrylic ≤100 ≥15 24 120 150 P3110 Translucent 100 Tissue Acrylic ≤100 ≥11 24 40 60 P3112 Translucent 120 Tissue Acrylic ≤100 ≥13 24 40 60 P3114 Translucent 140 Tissue Acrylic ≤100 ≥14 24 40 60 P3116 Translucent 160 Tissue Acrylic ≤100 ≥15 24 40 60 P3100G Translucent 70-160 Tissue Acrylic ≤150 ≥9-20 2 30 40 P3100G1 Translucent 70-120 Tissue Acrylic ≤120 ≥9-14 20 30 40 P3100HM Translucent/Yellow 60-140 Tissue hot melt glue winter≤200

summer≤100winter≥6-20

summer≥8-15winter≥0.5-3

summer≥1-630 40

The Double-Sided Transfer Tape is suitable for a wider temperature range and harsh environments, with long-term temperature resistance of 80 to 150 degrees Celsius and short-term temperature resistance of up to 200 degrees Celsius. Common thickness specifications are 0.05 to 0.13 mm. It has excellent waterproof performance, dimensional stability, thermal stability, and can be applied to a wider temperature range and harsh environments.