What is Protection Film Tape?

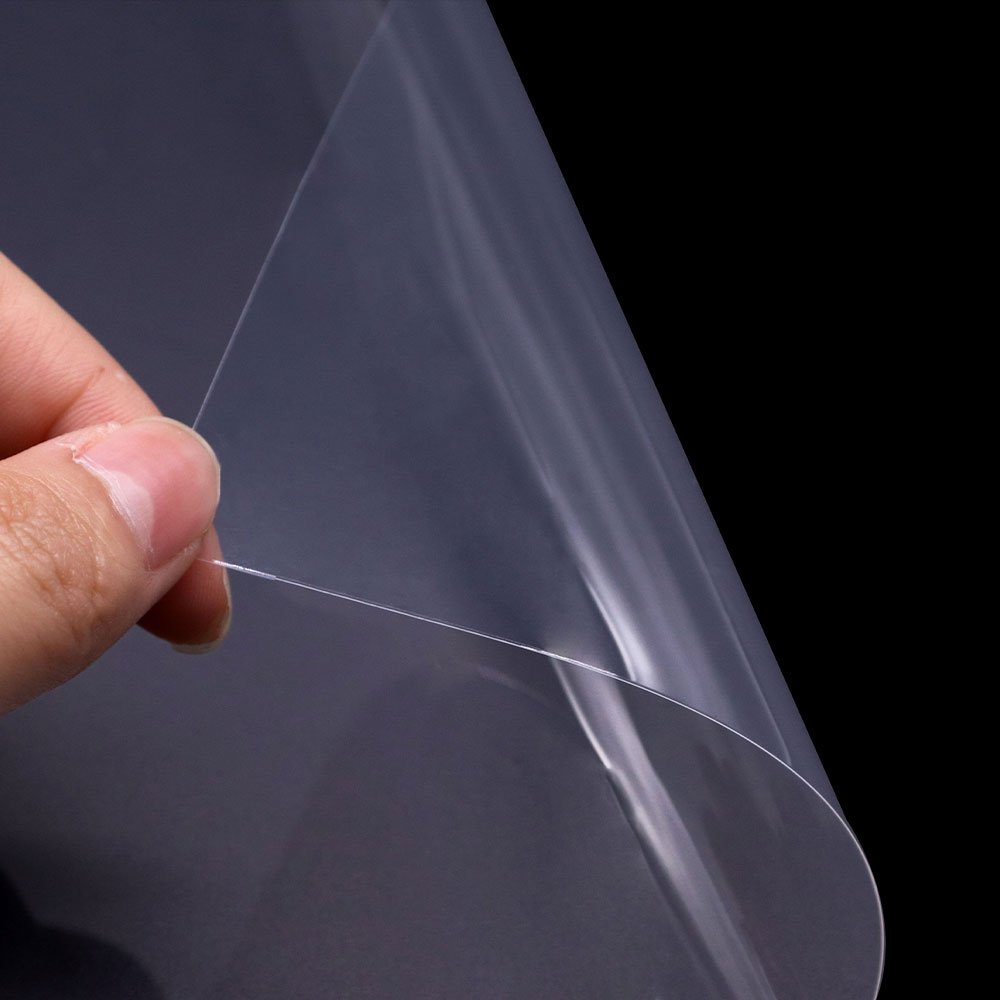

In their simplest form, a temporary surface protection film is a thickness of plastic coated with a thickness of a specialized pressure sensitive adhesive (PSA). A key word when describing protective film adhesives is “temporary.” By design, a temporary surface protection film is not intended to be left on a surface indefinitely. We have all experienced the irritation of trying to remove a supposedly temporary price tag from a new gizmo and the tag tore into strips and/or left a gooey residue behind. That is quite undesirable in a protective film. Read How to Select a Protective Film to avoid having that happen with your protective film.

The most common plastic types used in protective films are

LDPE (low density polyethylene),

Co-Ex (co-extruded low density polyethylene),

PV

PVC is typically a bit more expensive and is used in special applications, such as metal forming and exterior window protection where the film will be exposed to sunlight for up to a year. LDPE that has been treated with UV inhibitors can also be used for exterior applications. To avoid problems, do not use an interior-rated film on exterior applications.

Film thickness is normally described as the combined thickness of the plastic and that of the adhesive. In the USA, film is measured in thousands of an inch, or mils. (This is not the same as millimeters.) Typical film thicknesses range from 1 mil to 6 mil, occasionally higher. The thicker the film, the more protection it offers against abrasions, scratching, etc. Thicker films tend to be more rigid and can be more difficult to apply to contoured surfaces.

Adhesive type is also an important consideration. Textured surfaces usually require thicker and softer adhesives. If the adhesive is just contacting the “peaks” of the surface, it may be touching less than 5% of the total surface area and be prone to falling off the surface. Adhesives for textured surfaces also tend to be higher in tack value.

Tack, or adhesive stickiness, is measured in ounces per inch. For best performance, it is desirable to use the lowest tack value that adheres sufficiently well enough to keep the film on the surface during its life cycle. Using a higher tack level than is necessary can increase the risk of the film being difficult to remove or of leaving adhesive residue behind. For example, protective films that are used to protect the LCD screens on cell phones have a tack of about one ounce/inch. Films that are used to protect carpeting have a tack of 25 ounces/inch or higher. Using carpet film on an LCD display would probably pull the display apart when the film was removed.

Reference the Application Charts for a number of suggested protective films for various surface types. And, the How to Select A Temporary Surface Protection Film can help you get the selection process underway.

How Long dose the Protective Film tape Take?

why is the life of Protective Film Tape so much shorter? The answer lies in the magnetic charge. Over time, the magnetic particles lose charge in a phenomenon called remanence decay. This causes discoloration, blacked out scenes, and eventually complete loss of footage. The best way to preserve tapes is to store them in a cool and dry place with little to no climate change. But keep in mind even the best quality tapes stored in optimal conditions will succumb to deterioration.

There are other eroding factors at play too. Here is a list of reasons why tapes might start deteriorating faster:

– Storing in hot conditions

– Storing in humid conditions

– Storing near a magnetic source (such as VCRs and loudspeakers)

– The tape was cheap or low quality

– The tape has experience excessive rewinds and playbacks

– The tape is a 2nd or 3rd generation recording copy

The best way to keep your memories is to convert your Protective Film Tape to digital files such as a DVD. It can digitize your Protective Film Tape to keep them safe for up to a century! Guaranteeing that even your great-great-grandchildren can watch your favorite childhood memories!