3M VHB Tape is widely used in computers, mobile phones, communications, home appliances, audio-visual equipment, automobiles, and other products. It should be selected according to the application product and environment needs. Please refer to the following instructions:

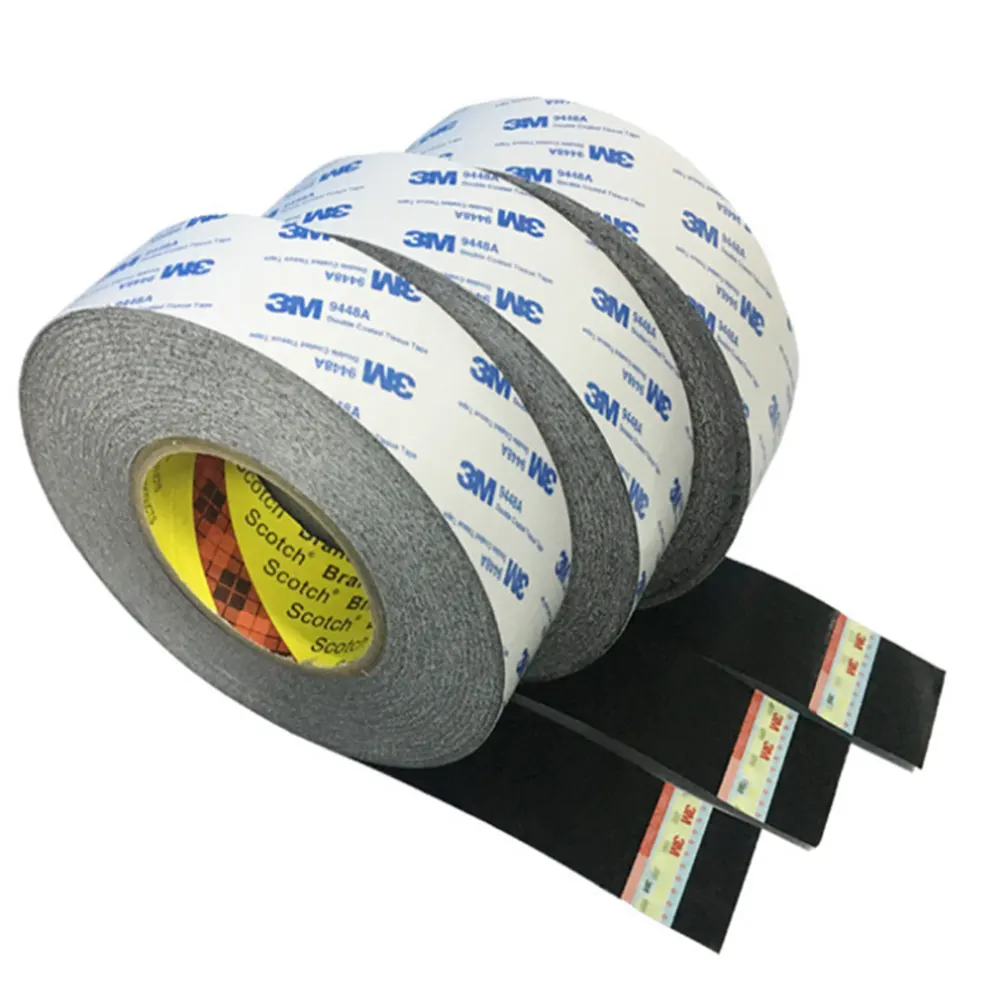

1. Non-woven substrate double-sided adhesive and good processability, generally long-term temperature resistance 70-80 ° C, short-term temperature resistance 100-120 ° C, thickness is generally 0.08-0.15MM, suitable for nameplate, plastic paste He, automobile, mobile phone, electrical appliance, sponge, rubber, signage, paper products, toys and other industries, assembly of home appliances and electronic instruments, display lenses.

2. The non-substrate double-sided adhesive has excellent adhesion effect, can prevent falling off and excellent waterproof performance, good processability, good temperature resistance, short-term temperature resistance 204-230 ° C, general long-term temperature resistance 120-145 ° C, The thickness is generally 0.05-0.13MM, which is suitable for the bonding of nameplates, panels, and decorative parts.

3. PET substrate double-sided adhesive has good temperature resistance and strong shear resistance, generally, long-term temperature resistance of 100-125 ° C, short-term temperature resistance of 150-200 ° C, the thickness is generally 0.048-0.2MM, suitable for the nameplate, LCD, the decoration of decorative items and decorative parts.

4. Double Sided Foam Tape has softness, good applicability, good initial tack, and good adhesion, good solvent resistance, and UV resistance, generally 0.4-1.0MM thickness, short-term temperature resistance 130-150°C, long-term temperature resistance 80- 93 ° C, suitable for the bonding of air conditioners, office furniture, communication products, can replace the screw fixing design to make the products more beautiful.

5. The hot melt adhesive film has good consistency, uniform bonding thickness, no solvent, easy processing, and good adhesion to many objects. The thickness is 0.1MM, the color is translucent/amber, and the hot-melt softening temperature is 116-123 °C. Applicable to the bonding of nameplates, plastics, and hardware; good results can also be obtained by bonding on the surface of uneven objects. Die Cutting 3M Tape Factory recommends initial bonding conditions of 132-138 ° C, bonding time 1-2 seconds, and pressure 10-20 psi.

3M VHB tape is tough, temperature-resistant, conformable, discreet, and used to attach dissimilar materials. It offers many benefits as an alternative to mechanical fasteners and expands in usage as it continues to make its name in the industry.

1. IT’S ONE OF THE TOUGHEST MATERIALS OUT THERE

3M VHB tape offers one of the strongest bonds out of any adhesive. In fact, VHB tape has been certified in the industry to have a powerful bond (it’s in the name: VHB = “Very High Bond”).

VHB’s adhesive properties give it an incredibly durable hold on any surface. Combined with its elastic properties, it can absorb the shock of any load, making it perfect for static and dynamic operations.

Furthermore, the tape’s potent adhesive mix makes it robust and long-lasting. 3M VHB tape can stay in place for many years and will continue doing its job just as well as when you applied it.

2. IT CAN WORK IN EXTREME TEMPERATURES

Every product is limited to the hot or cold conditions it functions in, and the same goes for tape. Most adhesives have a limited temperature range, with their cool spectrum capping off at 10 degrees Celsius or 50 degrees Fahrenheit.

3M VHB double-sided tape is much more durable than your everyday tape, withstanding freezing temperatures of 0 degrees Celsius or 32 degrees Fahrenheit.

3. VHB TAPE CAN MOLD TO ANY SHAPE

Your equipment may have a multitude of complex parts that are too challenging to fix with traditional adhesives. Not to mention, fasteners have a fixed shape that might not solve the problem.

The VHB adhesive’s contouring abilities allow it to stretch, squeeze, and otherwise shape itself around any surface with ease, and its foam-based material helps it flow into microscopic irregularities in the item and seal them all shut, guaranteeing a powerful and long-lasting bond.

4. IT ENABLES LOW-VISIBILITY CONNECTIONS

While you COULD hang your family photos using duct tape, there are several reasons why you’d probably use low-visibility adhesives.

Regular tape can be bulky, uneven, and highly dependent on the precision of your application. However, 3M designed certain 3M VHB tapes for subtle, thin bonding that is virtually invisible after application so that you can have smooth-looking results.

5. YOU CAN USE IT TO COMBINE DISSIMILAR MATERIALS

Dissimilar materials require double-sided differential tapes, a fancy way of calling adhesives that can hold together surfaces made from different materials. Traditional adhesives and fasteners may be limited in this regard.

In most cases, fasteners are designed only to fit a specific way within a particular material. While adhesives can be used on a decent range of surfaces, they are still limited to certain types of bonding depending on their material composition.

VHB tape can fasten together almost any surface you can throw at it and hold together surfaces made from entirely different materials. You can combine metal with wood, wood with plastic, or anything else your heart desires; the correct VHB tape will hold it together and offer guaranteed security.

How Does 3M VHB Tape Compare With Other Fasteners?

Depending on how long your business has run, you may have grown fond of traditional fasteners. However, sometimes, change is necessary to upgrade your business to new heights.

3M VHB tape is a consistent and reliable tool for many products, and to help demonstrate why people make the switch, we’ll compare the differences between VHB tape and fasteners.

A. IT’S CUSTOMIZABLE

While fasteners come in fixed, solid shapes, VHB tape offers a flexible, customizable solution.

Adhesive converters can slit VHB rolls into smaller quantities or cut them into custom shapes that better suit your project application. Not to mention, your converter may laminate multiple types of tape, adhesives, and liners to build custom material stack-ups that suit the surfaces to which you’re adhering.

B. THIN & SUBTLE ADHESIVE BOND

Mechanical fasteners often create uneven surfaces which can lead to geometric and aesthetic issues. Thin bonding VHB tape can act as a smooth, less visible, but equally powerful bonding material.

C. SERVES MULTIPLE PURPOSES

Unlike fasteners which only join surfaces together, VHB tape has sealing, gasketing, and vibration dampening abilities due to its foam composition.

D. LIGHTWEIGHT

Many industries require lightweight bonding solutions, and adhesive tape is far lighter than traditional metal fasteners. For instance, we’ve seen companies reduce the weight of their aircraft by using tape to bond seating components instead of screws. If you’re in need of a lightweight, yet sturdy solution, VHB tape could be a good choice for you.