Masking Tape was invented by Richard Drew in 1925 and has a history of nearly 100 years. It is a tape made of crepe paper as the base material and coated with different types of adhesives such as rubber, water-based glue, oil-based glue, and silicone according to different uses. It has the characteristics of high temperature resistance, good resistance to chemical solvents, high adhesion, softness and conformability, and no residual glue left after tearing off. This is an easy-to-remove tape that is mainly used for spray paint masking and protection, construction site sealing and protection, temporary fixing of electronic components, ceramic tile joints, temporary limited margins, etc. Widely used in various fields, such as decoration, automobile, electronics, electrical appliances, electroplating, packaging, shoe industry, etc.

Typical structures of Masking Tape

The production process of Masking Tape starts with ordinary crepe paper or Washi paper. After impregnation, one side is coated with a release agent and the other side is coated with adhesive. As shown in the figure, the structure of masking paper from left to right is release agent, functional coating, sizing agent, functional coating, and pressure-sensitive adhesive.

Structure details:

The sizing agent is generally based on styrene-butadiene emulsion, which is mainly used to enhance the physical properties of the paper and can block the isolation layer and adhesive layer.

Release agent is a release coating applied on the back of the tape to allow the tape to unfold smoothly. Some products can also improve the surface water resistance of the tape.

Functional coating can improve the bonding force between different coatings or provide the tape with some special properties, such as solvent resistance.

The adhesive layer is generally based on natural rubber or acrylic systems, providing the adhesive properties of the tape on different substrate surfaces.

Types of Masking Tape

1.Rubber Masking Tape: Made of textured paper that has been impregnated and released and then coated with rubber pressure-sensitive adhesive.

2.Comprehensive-purpose Masking Tape: Mainly used in indoor home decoration, outdoor construction paint, spray paint masking or package fixation.

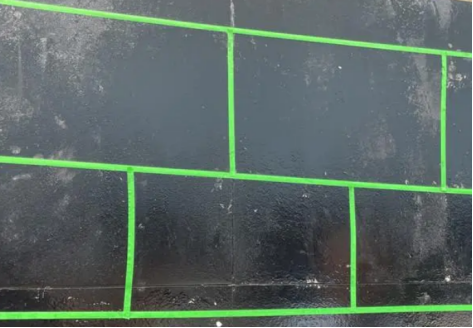

Indoor home decoration:

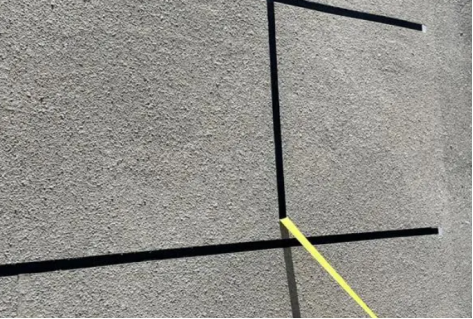

outdoor construction:

3M 2214 Temperature resistance 90 degrees

tesa 4338 Temperature resistance 120 degrees

Auto repair and aviation spray paint Masking Tape: Mainly used in spray paint masking in automobile manufacturing, automobile maintenance and aerospace.

yousan P1773

tesa 4302 Temperature resistance 160 degrees

nitto P-703 Temperature resistance 148degrees

Industrial Masking Tape: Mainly used in electronic braiding, high-temperature industrial bundling, shoe material spray painting and masking, etc.

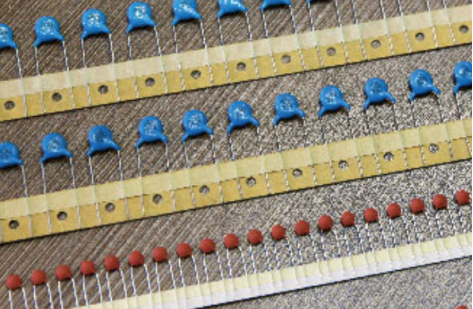

electronic braiding:

3M 200

High temperature industrial:

tesa 4330 Temperature resistance 140degrees

Water-based Masking Tape: Made of textured paper that has been impregnated, released, and then coated with acrylic pressure-sensitive adhesive.

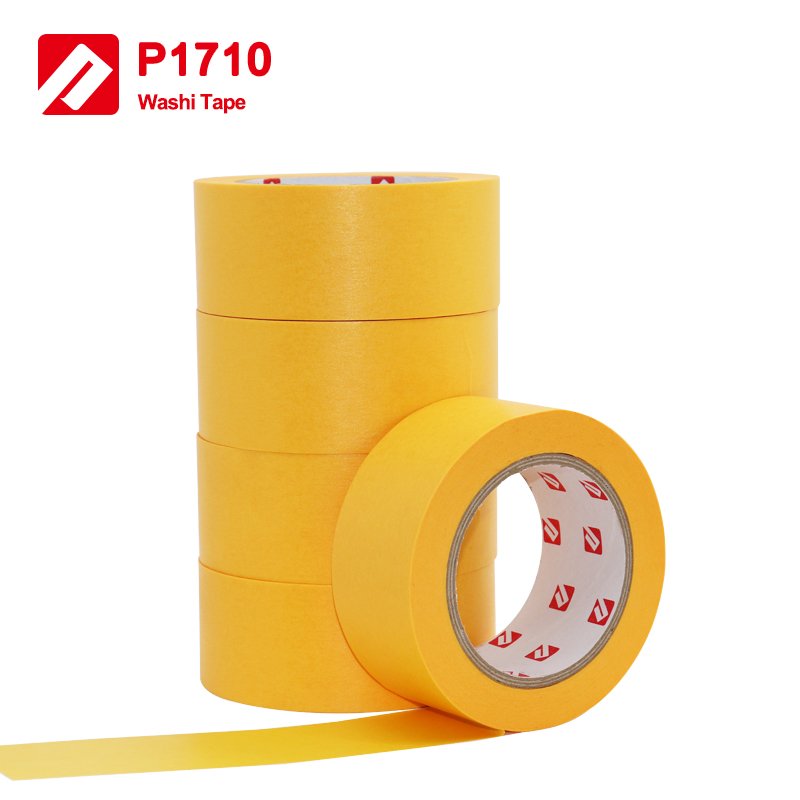

Auto repair and aviation spray paint Masking Tape: Mainly used in spray paint masking in automobile manufacturing, automobile maintenance and aerospace.

P1710

nitto 7239

3M 244 Temperature resistance 100degrees

tesa 4342 Temperature resistance 150degrees

Comprehensive-purpose Masking Tape: Mainly used in spray painting and painting masking during outdoor construction and indoor home decoration, or in package fixing.

Indoor home decoration:

nitto 720N

outdoor construction:

nitto 727

package fixation

3M Scotch C314-P67

nitto 720A

Silicone Masking Tape: Made of textured paper that has been impregnated, released, and then coated with silicone pressure-sensitive adhesive.

Industrial Masking Tape: Mainly used in electronic braiding, high-temperature industrial bundling, shoe material spray painting and masking, etc.

Shoes material processing: This type of tape is also commonly known as silicone tape.

P1714

High temperature industry

yousan P1720 Temperature resistance 180degrees