What is Foam Tape?

Foam tape is a type of pressure-sensitive self-adhesive tape that comes in various forms and is made from foam material. It may feature adhesive on one or both sides, depending on the application. Designed to adhere to uneven or textured surfaces, foam tape’s sponge-like properties allow it to conform to irregularities and secure surfaces effectively. Single-sided foam tapes are ideal for tasks such as sealing, while double-sided versions are useful for bonding two surfaces together. For surfaces with significant roughness or irregularities, a thicker foam tape may be necessary. Available in different foam types and with customizable adhesive sides, foam tapes cater to diverse substrate requirements.

Due to their versatility, foam tapes are utilized across multiple industries. They offer benefits such as cushioning, insulation, slip resistance, sound and vibration dampening, weather resistance, and ozone resistance.

Foam tapes are available in a range of forms including rolls, sheets, and die-cut shapes. Many foam tapes are easy to use, require no drying time, and are pressure-sensitive. Their adaptability and availability in various lengths, widths, thicknesses, and colors make foam tapes a highly versatile product, suitable for numerous applications and conditions across different sectors.

Foam tapes are available in various foam ranges, including open-cell and closed-cell foam in soft, medium, and hard densities. The principal ones are PVC, polyurethane, polyethylene, neoprene, EPDM, and other materials. One will choose the required range based on the application’s needs.

Foam Ranges

- Soft: Foam tape in the soft range is frequently used for air and dust sealing, as lightweight air and dust seals, lightweight cushioning, anti-vibration, and seals.

- Medium: Foam tape in the medium range is frequently used as a separator to cover gaps, to cushion surfaces, seal seams, and reduce heat transmission.

- Firm: Where low compression is required, athletic range foam tape is frequently used for sealing, slide pads, glass protection, vibration and sound dampening, and high load-bearing applications.

Properties of Foam Tapes

Foam tapes are available in a diverse array of thicknesses, adhesives, carriers, sizes, and cell structures, allowing them to be tailored for numerous applications and end uses. Each type of foam tape offers specific characteristics and benefits that make it well-suited for particular tasks.

- Because foam tape is so flexible, it may be used to fill gaps and conform to link unusual surfaces.

- Foam tape can often tolerate temperatures between -40°F and 300°F (-40°C to 200°C).

- Offers strong bonding to account for various thermal expansions.

- Foam tape has a high adhesive strength for various temperature expansions and is resistant to moisture, ultraviolet light from the sun, and solvents.

- Excellent shock absorption protection and good resistance to compression deformation are provided by this seal, which keeps out dust and moisture or prevents outgassing.

- Environmentally friendly, free of toxic ingredients, and flame resistant.

- Excellent wettability, ease of die-cutting, suitability for bonding and fixing of varied sizes, and ability to complete watertight sealing are all surface features. Other features include high adhesion, good weather resistance, and resistance to acid and alkali.

How Foam Tape is Used

Joining Items

tiny die-cast components, and other materials can be combined with double-sided tape for attaching two materials, especially those with rough or irregular surfaces; foam tape with double-sided high-performance adhesive works great for this purpose. Acids, oils, grease, and humidity won’t damage this tape. It is available in black or white foam.

Mounting

Foam tape is highly effective for mounting or hanging large objects. For instance, it can be used to attach point-of-sale signage, mirrors, photos, towel hooks, and bars in retail settings.

Cushioning Surfaces

Foam tape is effective for sealing gaps that would otherwise permit air, water, or dust infiltration. By padding the space between two surfaces, it helps prevent damage, reduces heating or cooling costs, and keeps moisture out. Additionally, foam tape can protect paint from scratches caused by heavy mirrors or picture frames.

Insulation

Insulation foam tapes are effective for insulation because they can retain heat.

Vibration Reduction

Foam tape can help reduce noise and vibrations in machinery or audio equipment. It is also useful in high-pressure environments to mitigate vibrations that might cause damage.

Light-Blocking

Foam tapes can effectively block light from tiny holes, gaps, and voids in doors and windows.

Mechanical Fastening

Foam tape can be used instead of mechanical fasteners such as screws or nuts, which might be costly and could cause friction in high-pressure environments like automotive applications. It is preferable when avoiding puncture holes and is often seen as a more aesthetically pleasing option as it can be hidden behind surfaces.

Considerations When Using Foam Tapes

Choosing the right foam tape for an application requires careful attention to its specific characteristics. It is important to select the correct width, thickness, and adhesive type for the task. Additionally, understanding which type of adhesive best meets your needs is crucial when making a purchase. Options include rubber, polyethylene foam tape, and acrylic foam tape. Selecting the most suitable foam tape is essential for achieving successful results in your final products.

Guide to Manufacturers

Always read the manufacturer’s warnings and instructions before using any product. These guidelines will provide direction for the specific applications of the tapes, which come in various forms.

Design and Handling

The method of applying the tape, whether automated or manual, is as important as the tape’s strength.

Conformability to Application

Foam tapes are made with a flexible foam carrier that bridges gaps and connects uneven surfaces. Depending on the project’s needs, foam offers cushioning, stress absorption, and vibration dampening, making it versatile for many applications.

How Soon it Sticks

It is important to consider how soon the foam tape adheres to a given surface. The time required for the tape to stick can vary, and this should be taken into account for planning purposes. The amount of pressure applied also affects the sticking time.

Bonding

Consider the surfaces on which the tape will be applied. Foam tapes generally have a strong, quick-stick adhesive that bonds effectively to a range of surfaces, including wood, plastics, chipboard, and corrugated metal.

Preparation of the Surface and Pressure

For a strong bond, thorough surface preparation is essential. Contaminants such as dirt, oil, dust, paint, release agents, or other substances on the material’s surface can interfere with the adhesive and weaken the bond. Ensure surfaces are dry and clean before applying the tape. A common cleaning solvent is rubbing alcohol. If necessary, dry the area with a clean, lint-free cloth to ensure it is completely dry. Apply firm pressure within the recommended temperature range for better contact as per the product instructions. Push firmly and evenly across the tape’s surface to activate the adhesive.

what are the different types of foam tapes and adhesives used on them?

Foam Cell Structure

Foam cell shapes are classified into two types: open-cell and closed-cell.

Open Cell Foam

Interconnected, softer, more breathable, and simpler to compress are the characteristics of open-cell foam cells. Because of its great porosity, the cell shape in an open-cell foam arrangement allows water, solid particles, and air to pass through the foam material. These foams typically weigh between 1 1/2 and 3 1/4 pounds per cubic foot, making them lighter than conventional. Open-cell foams are soft to the touch, absorb much water, and compress quickly. They are appropriate for sound-absorbing uses, including air conditioner sealing strips and compressed sponges for earbuds, among others. Due to their low density and the substantial ability for expansion and contraction, these foam varieties make packaging and transportation simpler. Although this open-cell foam has good soundproofing properties, it can also trap particles like dust and is mold resistant.

Common materials used for manufacturing open-cell foams include EPDM rubber, urethane foam, polyester urethane, polyether urethane, nitrile, open-cell sponge, sponge rubber, felt, melamine foam, and polyimide foam.

Closed Cell Foam

The bubble walls entirely enclose closed-cell foam bubbles. The bubbles are relatively stiff because they cannot be easily crushed. On the other hand, closed-cell foam structures stop everything from passing through the tape, including liquids, small solid particles, and air. Closed-cell foam is suitable for sealing, dust proofing, waterproofing, and shock absorption of electronic equipment. It has low compression residual rate, low water absorption, good thermal insulation, and cushioning performance. These foams may initially cost more, but they are more affordable over time because of their higher density and improved resistance to moisture and air. They fulfill functions like soundproofing and protective packing because of these advantageous traits. Polyethylene, silicone, PVC, cork, nitrile sponge blend, EVA, neoprene, nitrile foam rubber, and SBR foam rubber are materials used to make closed-cell foam.

Types of Foam Tapes

Foam tape is available in both single-sided and double-sided versions. The distinction between them lies in whether the adhesive is applied to one side or both sides of the tape. Each type offers specific benefits and is suited for different uses.

Foam Tape with Adhesive on One Side

Single-sided foam tape is commonly utilized for applications like sealing and providing anti-slip properties. It offers a reliable solution for diverse installation environments and is easy to trim and apply. This type is particularly suitable for uneven surfaces or situations where expansion or contraction could occur. Additionally, some single-sided foam tapes use compression to seal against elements such as air, dust, or moisture, depending on the materials used.

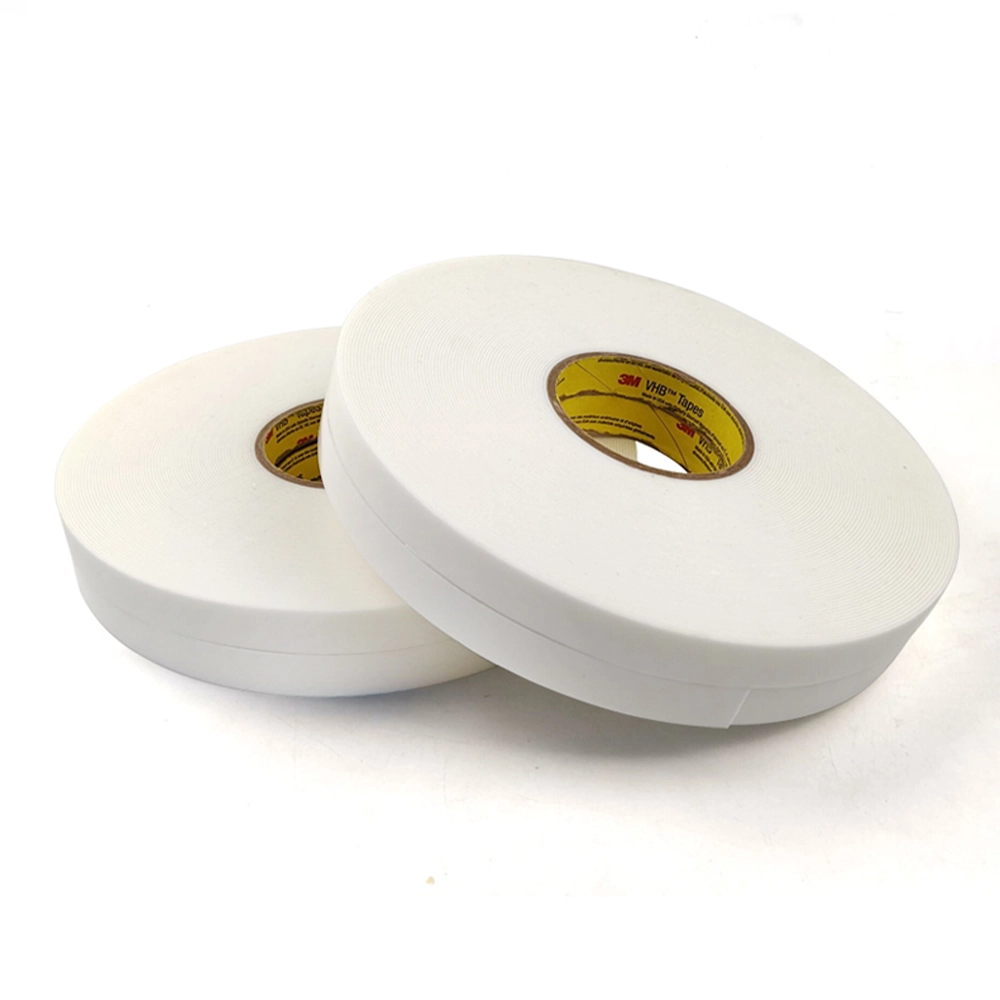

Foam Tape with Adhesive on Two Sides

Double-sided foam tape has various applications, such as mounting and adhesive bonding. It is particularly effective for quickly and securely joining two uneven surfaces. This type of tape is also well-suited for environments with significant temperature fluctuations, as it can handle materials with differing expansion rates. The flexibility and efficient stress distribution offered by double-sided foam tape make it an excellent choice for these conditions.

Types of Foam Tapes

The classification of foam tape can also be based on the type of backing material used. Here are some examples of the main types:

Neoprene and EPDM Foam Blend

Neoprene EPDM foam features either a rubber- or acrylic-based adhesive on one or both sides of the closed-cell foam, which is available in black or gray. This foam comes in various densities and thicknesses, including soft, medium, and firm options. Neoprene EPDM foam tape is suitable for both indoor and outdoor use and is ideal for sealing and weatherstripping applications.

Neoprene EPDM is well-suited for vibration dampening, weatherstripping, and gasket applications. It can withstand a range of temperatures and offers resistance to acids, alkalis, ozone, and oxidation.

Acrylic Foam Tape

The extremely flexible acrylic adhesive is elastic and flexible. It has a high level of strength and long-lasting durability. Acrylic foam tape has a comparatively strong adhesive bond, making it perfect for projects exposed to the elements, especially wetness or hot or fluctuating temperatures. In addition, it is resistant to chemicals and elements. One can pick an acrylic adhesive based on these qualities to seal a window or repair an HVAC system.

Acrylic foam tape is effective for attaching outdoor objects that are exposed to high heat and moisture. It also functions as weather stripping, insulation, a seal for HVAC systems to handle temperature fluctuations, and gaskets for garage or shed doors.

Polyurethane Tapes

Polyurethane is another commonly used material for foam tapes. It is a robust and durable substance capable of withstanding high temperatures. This versatile foam is suitable for both indoor and outdoor applications. Additionally, low-density polyurethane foam tapes provide effective insulation.

- Polyester Foam: Available in densities ranging from 1.5 to 6 pounds per cubic foot, this open-cell, non-reticulated foam is charcoal grey in appearance. Polyether foams are excellent for light insulation and sound and dust barriers. With various adhesives, polyester foams can be laminated to fulfill the needs of any particular application. Compared to polyether, polyester foams are more resistant to alcohols and hydrocarbons.

- Polyether Foam: Available in densities ranging from 1-5.5 pounds per cubic foot, this open-cell, non-reticulated foam appears grey. Although they perform better in moist or wet situations than polyester foams, polyether foams have a lower tensile strength. Polyether foams are also easily produced to customer requirements and can be provided with or without glue.

PVC Vinyl Foam

Ideal for applications requiring long-term outdoor exposure and impact cushioning, PVC vinyl closed-cell foam is available in various thicknesses and densities, typically in black or grey. It can be ordered with or without adhesive. PVC foams are commonly used in seals and gaskets to block air, dust, and mild moisture. They can be customized to meet specific requirements and are resistant to most solvents and chemicals. PVC foam tape also offers a reliable and chemically stable adhesive solution, available in multiple lengths, widths, and thicknesses.

Polyethylene (PE) Foam Tape

Foam tapes are often applied to polyethylene, a type of plastic known for its smooth, lightweight nature and ease of handling. Polyethylene foam tapes feature a conformable closed-cell foam combined with a rubber-based adhesive. This adhesive initially bonds well to various surfaces. Consequently, polyethylene foam tapes come in a range of thicknesses and widths. They are available in white or black with adhesive on one or both sides, catering to different application needs. Polyethylene foam tape is ideal for connecting, mounting, sealing, and gasketing. Common uses include POP displays, nameplates, signs, and mounting clips for wires and cables. The increasing demand for polyethylene foam tape often requires specialized manufacturing.

PE foam tape is particularly effective in reducing noise and vibration and accommodating materials that expand or contract at different rates. It adheres well to uneven surfaces and is suitable for indoor use on surfaces such as plastic. Its exceptional conformability makes it adaptable to surfaces with varying textures and rough edges. Additionally, its excellent compressibility makes it a good choice for padding. PE foams are a cost-effective solution for sealing doors and providing durable waterproofing between surfaces. They also do not release harmful pollutants when burned.

Rubber Foam Tapes

Traditionally, rubber has been used as the base for foam tapes. This natural material is strong and durable, with excellent abrasion resistance and the ability to withstand high temperatures. Rubber foam tape is known for its self-adhesive qualities, strength, durability, and slight compressibility. It serves various purposes, including as gaskets and weatherstrips to support and stabilize large appliances. Additionally, it is effective in reducing rattles, vibrations, and squeaks in vehicles such as cars, trucks, and boats.

Silicone Foam Tapes

Foam tapes often use silicone, a synthetic material, as their adhesive base. Silicone foam tape is ideal for sealing and gasket applications that require temperatures exceeding 150 degrees. It is also suitable for food-safe applications and has widespread use in industries such as aerospace, heavy engineering, marine, and space research. This type of tape is designed to achieve high performance and quality standards. Available in various thicknesses, silicone foam tape offers excellent insulating properties and provides a strong, reliable bond for high-temperature gaskets, insulation, and spacers.

Neoprene/EPDM/SBR Foam Tapes

Neoprene, EPDM, and SBR are combined in a closed-cell foam blend to produce a gasket component suitable for a variety of industrial and mechanical uses where durability, flexibility, and cost-effectiveness are important. This blend takes advantage of the strengths of each polymer to create a versatile product suitable for numerous indoor and outdoor applications. Neoprene/EPDM/SBR blends are also utilized in electrical enclosures, encapsulating machinery and enclosures that house electrical components and circuitry. This blend is particularly advantageous for HVAC systems as it effectively seals connections, ducts, panel doors, and other areas to prevent air leakage. The closed-cell neoprene/EPDM/SBR blend is ideal for weatherproofing and gaskets, operating effectively within temperature ranges from -40°F to +200°F. Its resistance to sunlight, ozone, and oxidation makes it an excellent choice for many outdoor applications.

The automotive industry can also benefit from this type of foam tape. The closed-cell structure of most pressure-sensitive adhesive tapes allows them to adhere effectively to metal and plastic surfaces for sealing and cushioning purposes.

Neoprene/EPDM/SBR blends offer a versatile gasket material that is frequently affordable and effective in various applications. If necessary, a pressure-sensitive adhesive (PSA) can be laminated onto one or both sides of this material. After that, the material can be trimmed to size and is frequently offered in various thicknesses. These blends can also be precisely die cut, or sliced to width.

Types of Adhesives on Foam Tapes

The three most common types of adhesives used in foam tape are acrylic adhesive, rubber adhesive, and silicone adhesive.

- Acrylic Adhesive: The most typical adhesive for foam glue is an acrylic adhesive. Acrylic foam tape is ideal for indoor and outdoor applications because of its strength, high-temperature tolerance, and excellent UV resistance.

- Rubber Adhesive: High viscosity and water resistance are two qualities for which this adhesive is known. Both smooth and rough surfaces can be used with it.

- Silicone Adhesive: This adhesive is renowned for being flexible and heat resistant. Both indoor and outdoor use are appropriate for it.

What are the applications foam tapes?

Applications of Foam Tapes

Many enterprises and sectors can benefit from using foam tape. Here are a few situations where foam tape may be useful and necessary:

Medical Industry

Foam tapes enhance infectious disease containment (IDC) equipment, which is especially beneficial in the medical field. They can be used to pad, seal, and insulate items such as splash guards and face masks. It is recommended that personal protective equipment (PPE) be lined with foam tape to ensure a proper seal and prevent contamination from bodily fluids and infectious agents.

Vehicle Industry

Acrylic foam tape with dual sides is ideal for securely fastening body edges and curves. It adheres strongly to various surfaces, including paint and external car parts. Because the body and external components expand and contract differently due to thermal changes, foam tape is effective in distributing stress. It also plays a significant role in noise reduction and providing watertight sealing for external trims.

Solar Industry

In the solar industry, foam tapes are used to bond components such as module back beams and concentrators that must endure harsh conditions. The quick-bonding capability of foam tape allows for fast and reliable assembly without compromising quality or requiring extensive curing time.

Gasketing

Foam tape is commonly utilized as gasketing tape. Adhesive-coated foam tapes act as compressible sealants to close gaps between machine parts or around pipe joints, preventing gas, fluid, air, or sound from escaping. Applications include sealing garage doors, shed doors, and electrical enclosures. Foam tapes can serve as an alternative to rubber foams, pumpable sealants, and caulks.

Weatherstripping Uses

Foam tape is often used for weatherstripping applications. It is typically applied along doors and windows to keep cold air out during the winter and hot air out during the summer. Foam tape effectively fills gaps where seals around windows or doors are inadequate, providing a reliable, long-lasting, and cost-effective alternative to replacements.

Appliances

Foam tape simplifies the process of fixing translucent or transparent decorative panels on home appliances. Its invisible bonding ensures a clean appearance, absorbs vibrations to minimize noise, and provides strong adhesion to surfaces with low surface energy, such as plastics. Vinyl foam tape is also versatile for sealing HVAC systems and preventing drafts in homes due to its water resistance.

Building Renovation

Foam tape can be used for repairs, adhesion, or insulation in homes or commercial buildings by professional handymen or women. It is also suitable for use by office workers, restaurant managers, and other personnel for various repair tasks.

Wind Energy

In the wind energy sector, foam tapes are used to join exterior components of wind blades, such as deflectors and serrated trailing edges. Foam adhesives help reduce assembly times and enhance blade processing in factories. They provide excellent stress dispersion and weather resistance for both outdoor and indoor applications.

Electronic Products

Double-sided foam tape is ideal for bonding touch screens, windows, and backplanes on electronic devices like smartphones and tablets. With the increasing popularity of narrow bezel designs, foam tape ensures that cover glass remains securely attached, protecting against impact forces from drops and collisions. Urethane foam tape also helps reduce sound in electronic devices, such as keyboards and printers.

Transportation

Foam tape is effective for assembling parts in the ceilings, walls, and floors of trains, high-speed rail, and airplanes. It enables secure and compliant fastening according to established standards.

Architecture

- Indoor Wall Covering: Changing a room’s aesthetics quickly and affordably without employing a pricey designer or contractor is possible with foam tape. One can change every surface into something new with just one piece. In addition, panels can be swiftly and neatly installed using tape without causing material damage or waiting for the adhesive to cure.

- Furniture Decorative Panel Fixing: To provide cabinets or closets with an attractive appearance, decorative panels made of glass, wood, and glazing are often found there. The foam tape supports a certain amount of the panel’s weight, which can be supported by the foam tape, which also completes a solid and long-lasting fixation between various materials.

- Glass Partition Wall Bonding: Aluminum or glass profiles can be combined using double-sided foam tape. This material’s transparency produces an undetectable bonding effect for partition walls that is ideal for filling in any gaps in the project.

- Curtain Wall Bonding: Decorative walls can be covered to create striking architectural façades. Because they produce a cleaner and more aesthetically-pleasing look while meeting the strict requirements of external weather resistance, foam tapes are a great substitute for conventional mechanical fixing methods.

Benefits of Foam Tape

Foam tape is highly adaptable and can be customized to fit nearly any application. Consequently, foam tape offers numerous benefits, including a long service life, versatility, flexibility, and efficiency in terms of both time and cost.

- Saving Time: Foam tape saves time by replacing the requirement for fasteners, liners, and sealing materials when used as an interior adhesive in devices and equipment. This device can dramatically reduce overall manufacturing labor and time requirements by requiring less waste management and installation time, increasing production efficiency.

- Material Cost Reduction: Foam tapes, which are cheap and simple to make and shape to precise measurements, can cut down on material costs. Suppliers can satisfy the project’s requirements by converting to tape using techniques like lathe splitting and die cutting. As a result, they deliver enormous rolls or logs with accuracy in dimensions while maintaining a low overhead cost for the materials.

- Longer Service Life: Extremely durable foam tapes maintain their characteristics in various challenging circumstances. Most significantly, the PVC foam tape is resistant to harm from fuels, flames, chemicals, solvents, and ultraviolet radiation. Furthermore, since PVC foam has a closed-cell structure, it doesn’t absorb moisture easily and won’t rot. In addition, PVC is vibration-resistant and has a great fatigue life. Given that PVC foam is resistant to many factors and still maintains compatibility with various adhesives and resins, it is a practical choice for a lifetime.

- Foam tapes are flexible and adaptive: they expand and contract due to temperature and atmospheric pressure variations, but they maintain a strong binding. Traditional fasteners will get looser during repeated expansion and contraction. Foam tapes are adaptable, bending with heat expansion and contracting to maintain their adhesive. They can use designs with double-sided adhesive, resistant linings, and specialty materials and are adaptable to fulfill the demands of any specific application.

Yousan TAPE is a professional industrial foam tapes manufacturer with 18 years of production experience and a leading position in China. Their professional research team can produce compliant products that meet various testing regulations.

Yousan TAPE uses quality materials in their manufacturing process to ensure the durability and longevity of their foam tape . This ensures optimal performance even in harsh environmental conditions, making it suitable for both indoor and outdoor applications.

By choosing Yousan Tape China, you can be sure that you are working with a reputable manufacturer, contact us today for all your foam tape